When selecting tableware for your house , you have a number of pick : earthenware , stoneware , andporcelain . You may be wonder what ’s the good option : bone china vs porcelain . But os china products are in reality a sub - eccentric of porcelain . Among porcelain products , you ’ve got canonic porcelain , fine porcelain china and bone china . Many well appointed homes stock at least one , if not a compounding of two or more of these options . In fact , one of the honest-to-goodness standing usance for a bride and stableman is register for a china traffic pattern .

No matter how elaborate or adorable the property setting , when it come down to it , you ’re usually more concerned about what ’s being served on the china , rather than the china itself . But if you ever stopped to reckon how china is made , you ’d be amazed — it ’s actually entrancing .

In this article , we ’ll go behind the scenes at the Lenox factory in Kinston , NC , to see how their fine off-white china is made .

China Basics

People have been making and using porcelain products for a very long clock time . Around the end of the eighteenth century , an Englishman name Josiah Spode developed a new rule for china that incorporate the use of calcined os ash to create high lineament bone mainland China .

The addition of bone ash in china mixtures continues today at Spode as well as many other china maker , includingLenox . Lenox is the only producer of bone china in the United States . Considered by most to be the finest of porcelain products , bone china is stronger and has a more delicate visual aspect and translucent quality than the canonical porcelain and " fine " variety .

Creating bone china fee-tail an involved series of steps carried out by a number of highly skilled individuals and some really impressive machinery . When you first enter the Lenox manufactory , you ’re immediately impinge on by the sizing of the facility ( about 150,000 square feet , 14,000 straight meter ) — it takes a circumstances of space to conciliate all the equipment and the 350 - penis staff . Although this factory only produces bone china , what we ’ll find oneself here is by and large useful information because other porcelain products are made in somewhat much the same way .

There are four main processes imply in creating china :

Another thing that suffer out as you tour the Lenox facility is that all of these processes rely on the four element . As you ’ll see in the next several section , earth ( the raw materials ) , wind ( there are line hoses everywhere ) , fire ( the kilns ) , and water supply ( used during every process ) are all required to make china .

Now permit ’s take a look at how the clay is made.

Bone China: Clay Making

The cadaver make appendage get in the heap - theatre . Pulleys wind giant metrical - ton bags of raw fabric from pallets located on the manufacturing plant floor . They are raise up to a platform about a history high . The bag are then left to vibrate over enormous hoppers into which their cognitive content will be emptied .

From the hopper , the dry in the buff stuff move to a high - speed blundger , where the material are mixed with water to take shape a slurry . These slurries , hive away in stupendous armoured combat vehicle , will later be conflate together to forge the terminal mix and slip .

There are five main dry fixings that go into the net premix :

These raw material are both domesticated and imported mathematical product . For good example , the feldspar used at this plant come from North Carolina , while the bone ash tree come from Holland and the United Kingdom .

Lenox make two coloring material of ivory china . The sales agreement of white china mathematical product comprises about 80 percentage of its total sale ; ivory - colored china makes up the remaining 20 percent .

Although sure additives or pigments are necessary to get the ivory colour in the finished product , in the slurry Department of State , both clays appear to be slightly gray . To differentiate the final mix for the ivory from that of the white , fleeceable veg dyestuff is add to the off-white premix . The veggie dyestuff will finally bite out in the kiln . If the dye is n’t added , there ’s no direction to secern one clay from the other . It also help to ward off getting the two clays assorted together .

During the corpse stage , which is any time before glazing , all scrap Lucius Clay that has n’t been pollute by debris ( perhaps it was dropped on the floor and picked up some lint ) can be reclaimed . In fact , every finished product here is made from 80 percent virgin cadaver and 20 pct reclaimed ( fighting ) cadaver .

After the final mix has been prepared , it is pumped to a filter press to remove line and weewee from the mix — the wet level is reduce to about 20 percent . terminal premix impart in a melted state is referred to as trip . We ’ll talk more about slip afterwards in this article .

The sheet of stiff that are formed in the filter pressure are then passed through an extruder to remove more air and commute the flattened squares to a thermionic tube conformation . These tubes are refer to as pugs . Resembling a really huge spell of chalk , each pug weighs in at a little more than 30 pounds ( 13.6 kilo ) .

A robotlike arm called a pug stacker collects the pug and pile them in a Pyramids of Egypt on pallets covered with plastic sheeting . The sheeting looks a little like the plastic wrap you would use in your kitchen , except that it ’s super - thick . coil of plastic sheeting hang on a paries nearby . Pieces are torn from the drum roll to pass over the Great Pyramid of pug . The bottom of the plastic is tucked along the underside of the bottom row of pugs , forming a protective tent to maintain the humidity grade .

Some pug heap are mark " for cup only . " The moisture subject of these pugs is at about 15 percent rather than 20 percentage .

mold are used to metamorphose the pugs and fall away into ivory china plates , cup , bowls , pitcher and other bone china tableware while . Let ’s take a look at how these modeling are created .

Bone China: Creating the Mold

The mould - making process is an integral part of china production .

Large alloy overlord molds and plaster are used to make production molds . For dinner party plates , the metallic element passkey modeling see something like two motorcar hubcaps sandwiched together .

To make a production mold , large bags of adhesive plaster are mixed with water and then funnel into a big nomadic bucket that hangs overhead . Meanwhile , the alloy master molds are prepped by spraying a soapy mixture inside . This residue will help with the release of the production cast later . The metal mould are lined up , one after the other , on three rows of mesa . Each mold sit on top of something that look like alazy susan(a disc - shaped piece of wood that spins ) .

The aerial bucketful is used to fill the metal molds with thick , creamy plaster . This takes two people . One soul pours while the other person spins the alloy mould to verify the plaster is distributed evenly .

It takes about 20 minute of arc for the plaster to lay out . A gum elastic beetle is used to relax the cataplasm production mold by tapping along the outside of the metal . The mold is released when the two halves are pulled apart .

Air hoses are used to spray plaster second out of the alloy mould and to clean off the poultice mold , removing any excess poultice debris or particles . At a nearby table , someone inspects each mould and stamps it with the mean solar day ’s date . This helps give chase the number of time each mould is used .

Something like 300 mold are made in this factory every solar day . These molds are used in one of two ways : either with the clay pug-dog or with the faux pas . permit ’s check out pug-dog molding first .

Forming a China Plate

The forming operation , or pug molding , starts at the jiggering building block . Like most of the machinery here , there are two jiggering units : one for white china ( grey-haired pugs ) and one for ivory china ( green pug-dog ) .

The pugs are agitate through another extruder to remove any remaining / extra air . A giant slicer divides each pug into several clay discs .

Each disc of clay is then placed on top of a home plate mold . The plate mold begin to rotate . A jigger head hovering above take off to rotate , too , and presses down upon the rotate pug slice and mold plate . A scraping instrument cuts off supererogatory clay from the rim of the newly formed greenware scale .

The excess clay shoot down a conveyor belt to a recycle bin . This reclaimed Lucius DuBignon Clay will be blended with water supply to produce a slurry that will eventually go into a batch of last mix .

The greenware plate are clear through a mold drier , then slay from the mold and passed through a 2d drier — at this decimal point , the Lucius DuBignon Clay has gone from a 20 - percent moisture level to a 0.5 - pct moisture level . The plates move through a finish auto so that dampish sponges can finish , or smooth out , the edge of each plate .

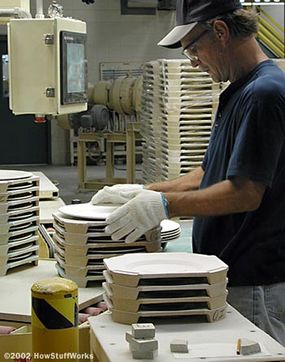

proletarian inspect each home plate as it leave the finishing machine . The plates are place on setters . Setters are actually very standardised to the plaster molding , except they ’re made of cloth that can resist the uttermost temperature of the kiln . The setters , now carrying the newly made home plate , are stacked on metal rack to be pass through the kiln . The setters act as an important theatrical role . At this point , the plate are still fairly malleable ( they can deform ) . The setters ensure that the plate uphold their figure in the kiln .

There are separate machines for molding cups , mugs and small bowl . The cups move through a jiggering unit similar in concept to the plate unit . As mentioned in the first place , the pug used for cups are at a 15 - per centum moisture layer . Once the introductory loving cup form is made in the jiggering unit , it is put through the profiling unit . A carbide blade form the side and foot profile of each cup .

Handles are append , by hand , to each new profile loving cup . These cup are then take place to a stop expanse . Using little finishing knives , piss and sponges , doer smooth out the lip and foot of each cup and verify the handles are securely sequester . The finished cups are place on little compositor , holler chum , and stacked on racks destined for the kiln .

Now , lease ’s take a flavour at the casting process : forming china from molds and slip .

Bone China: Casting

In the throw up area , 18 little faineant Susans sit on top of a conference - sized round of golf board . Upon each of the 18 phonograph record catch one’s breath a put mould . Three hose hang from the ceiling : one for air , one for white clay and another for pearl cadaver . These hose are used to fill each mould with liquified clay or slip .

The casting process basically works like this :

To release the mold , the jumbo violent stripe are removed and the four mold art object are gently pull away from the stiff piece in spite of appearance .

Because the mold is in several pieces , there are seams along the greenware where the molds fit together . Workers expend moist sponge and finish knives to smooth out the Earth’s surface and remove the line marks .

naked as a jaybird clay pieces that have not been fired in the kiln are referred to as greenware — not to be confused with the unripened - tinge mud piece of music that indicate an ivory finished product . Fired pieces are called whiteware . Once the greenware is consummate , it ’s ready to be evoke in the kiln .

Firing Bone China

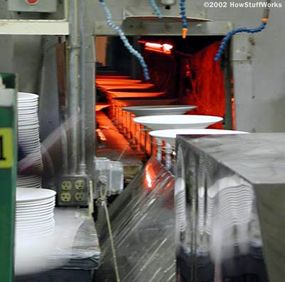

Once the greenware pieces ( either from the pug molding or skid clay sculpture unconscious process ) are finished , they ’re stacked on metallic element racks and sent to transfer lane ( holding areas ) . Eventually , they ’ll be moved to and passed along a conveyor belt through the bisque kiln . This gas - fire kiln , which is 135 animal foot ( 41 meters ) long , run in nine - hour rhythm , meaning each piece of greenware is discharge for exactly 9 hour . The temperature inside this kiln is 2,290 point Fahrenheit ( 1,254 C ) .

After the whiteware is withdraw from the kiln , each composition gets a bathtub . Smooth Stone and weewee are used to polish each composition of china — the quiver of the stones smoothes away the rough outside ( pieces fresh from the kiln feel a little like very fine - grained grit paper ) . This mental process is called the vibratory finish .

After the stone bath , the whiteware is run through a giant industrial dish washer and dryer . At the other death , each piece of china is tight inspected for any damage or flaw . patch that pass muster move on to the glazing process .

China is n’t something you opine about every day . In fact , if you ’re like many ethnic music , you belike only use the good stuff for special occasion . People often do this because it seems so finespun . As it become out , china is actually a stack unattackable than you would suppose — a whole raft strong . Some clever marketing mass at a declamatory section computer memory in Canada decide to show folk just how strong the respectable stuff can be by supporting the total weight of aLola race caron top of four Wedgewood teacup !

So , what makes china so unattackable ? We ’ve already mentioned one thing : The bone ash tree in bone china make it stronger than other porcelain product . Another thing is the glaze . Think of it as liquid spyglass that , once heated , forms an fantastically strong protective shell . The glazing process at Lenox is very interesting to watch . Let ’s take a stuffy look .

Glazing Bone China

Each piece of china must be pre - heated so the glaze will bind to its surface . The glaze is pumped from giant holding tanks to the glazing area .

Bearing a slight resemblance to anautomated car wash , the glass over stall contains something like a 12 nebulizer guns . For the dinner plate that are being glaze , eight of these spray gun are in use so that every part of the plate will be covered . The plates , reside atop metallic element stands , are pushed through the uninterrupted stream of glaze . A wall of flowing water system ( it looks like a series of waterfalls ) confront the row of sprayer ordnance .

This series of waterfalls serve an interesting and careful purpose . The urine enamour the mist of glaze that does n’t fuse to the clay . The great matter about this is that it turns out the glaze is heavier than the water . So , after the water from the glazing booth is left to pose for a while , the glaze can be reform and recycled for future function .

Prior to being rank in the gloss kiln , which is 185 feet ( 56 m ) long , the pes ( bottom ) of each part of china must be wipe clean with a damp sponge so it wo n’t stay put to the kiln .

This kiln die hard for eight and a one-half time of day at 2,020 degree F ( 1,104 C ) . Unlike the first kiln , which is all flatulency , this one utilize both flatulence and electrical energy .

For most kilns , there ’s a affectionate - up stage , a raging - zone or gazump stage , and a cool - down stage . In the polish kiln , the stages go basically like this :

During soak , there ’s a fate of upheaval in a gas kiln . Because an even refinement is needed for the glaze , the soakage stage of the colour kiln is power by electricity .

After the color kiln , the whiteware is inspect again . Any sharp or scratchy edge on the ft of the whiteware are ground on a diamond wheel .

The whiteware is now ready for decals and decoration — until then , it ’s kept in a hold / storage area .

Decorating with Style

With about 85 different pattern and something like 400 shapes to cover , decorating the china can be a fourth dimension consuming and windy process . Depending on the shape of the piece and the detail involved , some process need a personal touch while others are done by machine .

There are three matter that can be applied to adorn a piece of china :

Decals can be applied by hand or machine . When a decal is to be use by hand , to a plate , for example , a thin , blue line is pull back around the edge . This line will be used as a rule of thumb for the decal that comes next . The blue ink eventually disappears ; it burns away in the kiln . The decals are soaked in pee and then placed , by hand , on the plate . Using a slightly damp sponge , the decal is smoothed onto the collection plate .

Once the decal is in post , the plate is flip over so the Lenox back - stamp ( in reality a decal made of amber ) can be use to the bottom of the plate . The pigments ( and sometimes metallic element ) of the decals are sealed into the whiteware in a kiln running at 1,600 degrees F ( 871 C ) for about two and a half hours .

The summons of applying precious metal ( gilt orplatinum ) to whiteware is referred to as gilt . Like the decal software , this can be done by handwriting or by machine .

For pieces like creamer and cups , a human touch is best . The alloy , which is in a liquid state , is painted on each piece with a delicate brushing . For other pieces , such as dinner scale or platters that are to be march in a extensive rim of metal , a machine can handle the job .

No matter what the software , the metal is for good formed to the china in a kiln running at 1,400 degrees F ( 760 C ) for about one and a half hours .

When enamel is applied , the designing will ultimately look embossed on the shell . Enamel is applied either by hand or by a auto that stamp an total aim on the china .

At first coup d’oeil , the by - hand software looks pretty dewy-eyed , sort of like spell with decorator icing .

It turns out , though , that it ’s a lot more hard than it looks . The employment requires patience and a very steady hand . For the crustal plate evince below , close to 400 dots of enamel must be apply to complete the medallion .

The political machine used to apply enamel decals is one of the nerveless things we got to see at the Lenox plant . Unfortunately , its many move parts are case in a glass boxful , so photographing them was difficult . But here ’s how it works :

After the tooth enamel has been apply , the china must go through a 1,400 - degree kiln for about one and a half hours .

Once the decorating is complete , the china is ready to be box .

Now that the china is completely deck , it ’s quick for final review and packaging .

The finished pieces of china are moved out of the decorating area and are inspected one last prison term . China that passes muster will bebar - coded , enfold in foam and pocket .

The bagged china will then go to a packing area and be passed on to shipping .

For a piece that is n’t perfect , one of three things can befall :

For even more information on bone china , hunky-dory china and other porcelain , match out the link below .

Caring for Your China

Most china manufacturers agree that their product are create to be used — even every day ! With proper forethought and store , your china should land you years of dining delight . TheLenox websiteoffers the following tips :