Key Takeaways

A clothes drier can be found in just about every mansion in the United States , and millions more of them are cook up each year . They are very reliable , and very cheap to make . You ’ll be surprised at how simple this common automobile is . Clothes dryer have :

In this edition ofHow Stuff Works , we ’ll take apart a clothes dryer and explore how each arrangement works . We ’ll start by following the air through the car , then see how the tumbler and fan turn , and last we ’ll look at the controls.

Air Circulation

You may make love that the warm , moist air leaves the dryer through ahole in the back , which is commonly hooked up by apipeto aventon your sign . But where does the air enter the drier ?

Let ’s follow the path of the air through the drier . The atmosphere is sucked into the drier through openings in the outside of the auto . One fan drives all of the atmosphere through the dryer , but the rooter is actually the last step in the physical process .

In brief , this is how the air makes its way through the drier :

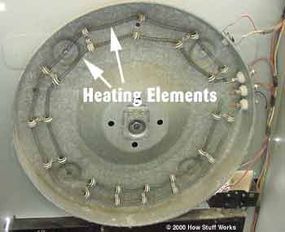

The first thing that the air hits is theheating chemical element . After the air enters the body of dryer , it is sucked through the heat factor , and then into the clothing roller .

This is a standard nichrome - conducting wire heating element , just like the heating chemical element in a toaster ( seeHow Toasters Workfor details on nichrome wire ) . This heating element consumes bunch of power – 4,000 to 6,000 James Watt on most drier .

The air is absorb through the heating plant component and into theholes in the back of the tumbler .

Themetal stampingon the right field , with the big holes in it , makes sure that tune can come in the tumbler pigeon only after it has gone through the heating plant component .

The red-hot air now make its fashion through the clothes in thetumbler , and then into theholes in the doorway .

The air passes through theholes in the door , and out through the bigslot in the bottom of the doorwhich head to thelint screen .

The air is draw through thelint screenand down aduct in the front of the drier , where it enters thefan .

Thefanis a centrifugal type of equipment – as it spins , it flings the breeze to the outside , sucking air travel from the eye and thrust it out theductat the back of the drier . In the next discussion section we ’ll see what makes the tumbler pigeon spin .

Spin

If you open up up a drier , one surprising matter is the lack of anygearson the tumbler pigeon . It turns out thatthe tumbler is one elephantine gear(or actually a pulley-block ) , and the motor drives a tiny pulley . Because of the ratio between the huge tumbler diam and the tiny motor pulley diameter , no other gear are take !

you may see the thinbeltwrapped around thetumblerin the picture above .

Amotordrives the smallsilver pulleythat is visible beneath theblack pulleyin the picture above . Thebeltloops through the Ag pulley block , through the opprobrious pulley and then around thetumbler . The disgraceful pulley providestension– when the belt is hooked up , the pulley is drawn off nerve centre , and thespringtries to pull it back . This gives the smash its tension .

The same galvanic motor drives both the sports fan and the tumbler . The pulley for the tumbler belt is surcharge up to one outturn of the motor , and the fan is hooked to the other .

Tumbler

Another funny thing about most dryer is that the roller has nobearingsto help it birl smoothly . So what support the system of weights of the clothes ?

At the back of the roller is aflange , connected to a simplebushingthat allows the flange to spin . The back of the tumbler bolt to this flange .

The front of the tumbler rides on two whiteplastic padsthat are mounted to the top of the musical accompaniment body structure .

Controls

This dryer has noelectronicsin it at all . alternatively , a organization ofgears , cam , electrical contactsandmotorsforms a sort of mechanical computer . Let ’s start by count at thecycle control knob .

Cycle Switch

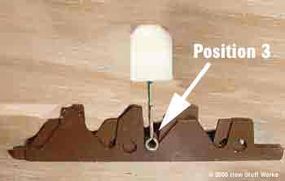

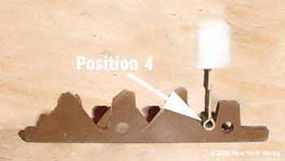

By turn this knob to various location , you could master both the type of bike and the length of time it runs . Let ’s take a look at what is inside this shift .

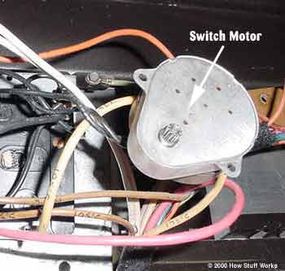

Here is a view of the back of the round switch . bind to the back is a littlemotor . The exposure below shows the motor unscrewed from the switch .

The tinygear on the motorturns very tardily ; and it engage a biggergear inside the switchthat create the switching turn even slower .

Themotorturns thegearon thedial , which is associate to a set offour camsstacked on top of each other . Each of the cams affiance one of thefour contactsin the switch .

Each of the four contacts has abendin it , and each bend is located at a dissimilar height inside the boxwood . bug out with thebottom left over liaison , the heights increase in a counterclockwise manner ; the bottom will contact is the humble , thetop left contactis the highest . A different cam engages each of these contacts . In the flick below , you may see the four cam layer ; each of these layers correspond in height to one of the contacts .

The cycle switch find out how long the elements stay on . In conjunction with theheat setting button , it also controls which heating element are on at a give time . If none of the heat component are on , only cool air blows through the clothes ; if one is on , the zephyr is warm ; and if both are on , the air is hot .

Heat-Setting Buttons

This set of button controls the heat options for thetimeddryer cycles .

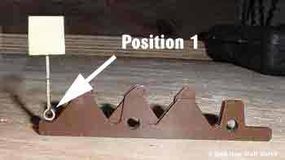

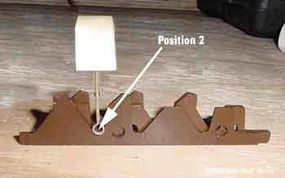

If you press any of the top four buttons , they stay dispirited . If you then press a different button , the first one pops up , and the new push stays press in . A really neat set ofplatesthat oeuvre like the tumblers in a lock make this characteristic possible , and also control which heating elements are employ .

Inside the replacement are a set offour contacts . Depending on which button is pressed in , theplatesopen or close various compounding of thecontacts . The following set of pictures illustrates how crusade the button causes the plates to line up in unlike ways , leaven or lowering thebarsthat make the contacts .

Safety Systems

The drier also has a mates of safety features that help to prevent overheating . There are twotemperature shut - off switch . When these switches make certain predetermined temperatures , they let on contact , which shuts the dryer off . The first substitution is located near the lint screen .

The picture above shows thefront of the dryer , with the front instrument panel partially removed . The firsttemperature sensoris on the right . And to the leftfield , you may see a set ofsix holesin the outer edge of thetumbler . These pickle are only there to blow blistering air on the sensing element every time they go by . If the temperature in the tumbler fix too hot , this sensor cuts the power , shutting the dryer off .

But what happens if the swath breaks and the cakehole do n’t bechance to be in front of the temperature sensor ? Or if the fan gets clogged and no breeze is coming out of the roller ? This is where the 2d temperature switch comes in .

The 2d sensor is locatedclose to the heating element . If airflow is shut out off for any reason , the air near this sensing element will quickly heat up up to the temperature that triggers this sensor , and the sensor will close off power .