Not too long ago , the musical theme of 3D printing process — produce three - dimensional physical object using machines that add layers of material on top of one another — seemed novel . If you say you ’re going to publish something from your figurer , most people still think of two - dimensional printing process , puttingtoneror ink on a slice of paper . Now , although many the great unwashed know what 3D printing is , they ’re in all likelihood marvel : How does a 3D printing machine work ?

3D printing uses a crime syndicate of manufacture technology called additive manufacture ( AM ) . AM is the means of make an object by add stuff to the aim , level by stratum . AM is the current terminology established by ASTM International ( formerly the American Society for Testing and Materials ) [ source : Gibson , et , al . ] .

This clause looks at the broad scope of 3D printing , from its chronicle and engineering to its wide scope of United States of America , including printing your own 3-D models at house . First , permit ’s take a flavor at how 3D printing got its start and how it is develop today .

History of 3D Printing

The earliest use of additive manufacturing was in rapid prototyping ( RP ) during the tardy eighties and early 1990s . Prototypesallow manufacturers a fortune to examine an aim ’s purpose more closely and even test it before produce a finished product . RP permit manufacturers to bring forth those image much faster than before , often within day or sometimes hours of conceiving the design .

In RP , designers make models using computer - aid design ( CAD)software , and then machines stick with that software simulation to determine how to construct the object . The process of building that object by " printing " its grumpy - sections bed by bed became known as 3D printing process .

The early ontogeny of3D printing technologieshappened at Massachusetts Institute of Technology ( MIT ) and at a company call 3D Systems . In the early 1990s , MIT develop a procedure it brandmark with the name 3-D Printing , which it officially abbreviated as 3DP . As of September 2019 , MIT has grant permit to six society to use and promote the 3DP cognitive process in its products [ source : MIT ] .

3D Systems , based in Rock Hill , South Carolina , has pioneered and used a variety of 3D printing process approach since its founding in 1986 . It has even brand some of its technologies , such as the stereolithography apparatus ( SLA ) and selective laser sinter ( SLS ) , each described later in this clause . While MIT and 3D Systems stay on loss leader in the field of 3D printing , other companies have also brought innovational new product to the professional market , building on these AM technology .

Bringing Digital Files Into Physical Space

Today , some of the same three-D impression applied science that contributed to RP is now being used to make ruined products . The engineering continues to improve in various ways , from the fineness of item a machine can publish to the amount of sentence require to clean and stop the object when the printing is complete . appendage are getting faster , the stuff and equipment are acquire meretricious , and more materials can be used , include metals and ceramics . printing process machines now range from the size of a small car to the sizing of a microwave oven .

linear manufacture is often compared to , or even mistaken for , another common manufacturing cognitive operation call computer numerical ensure ( CNC ) machining . However , CNC is an illustration of subtractive manufacture , which is the opposite of AM . In CNC machining , stuff is removed from some pre - existing pulley block until the finished merchandise remain , much like a carve a statue from stone , one layer at a sentence .

Now that you have some ground information about the field , let ’s search some 3D impression technologies .

Direct and Binder 3D Printing

One approach to 3D printing is direct 3D impression . Direct 3D printing process usesinkjettechnology , which has been usable for 2D printing since the 1960s [ source : Gibson , et al . ] . As in a 2D inkjet printing machine , nozzles in a 3D printing machine move back and forward dispensing a fluid . Unlike 2D impression , though , the nozzles or the printing surface move up and down so multiple layer of material can cover the same aerofoil . Moreover , these printers do n’t apply ink ; they dispense thick wax and plastic polymer , which solidify to organise each new crossing - section of the sturdy 3D object .

Rapid prototyping ( RP ) , which we described earlier in the article , has been a major factor in the increase of direct three-D printing . In 1994 , the ModelMaker , a machine produced by a company get laid as Solidscape , became the first commercially successful technology to apply the inkjet approach to RP [ author : Gibson , et al . ] . Other commercial RP mathematical product have followed , defying traditional manufacturing methods . For case , today ’s advanced speedy prototyping products use engineering science such as multi - green modeling ( MJM ) , which produce wax epitome quickly with twelve of nozzle work at the same time [ rootage : G.W.P. ] .

ligature 3D printing , like direct 3D printing , habituate inkjet nozzles to apply a liquid and form each young level . Unlike direct printing , though , binder impression habituate two separate materials that come together to imprint each printed stratum : a all right dry gunpowder plus a swimming glue , or reaper binder . Binder 3D printing machine make two passes to form each bed . The first pass rolls out a slight coating of the pulverization , and the 2nd go uses the nozzles to use the binder . The building platform then lowers slightly to adapt a new bed of pulverization , and the entire process repeats until the model is polish off .

MIT ’s 3DP procedure , note earlier , employ this ligature approach . MIT licenses company to develop product that utilise 3DP , but to qualify , the company must utilize some unique combination of powder and binder material . ring-binder 3D impression has a few advantages over lineal 3-D printing process . First , it tends to be faster than direct printing process because less of the fabric is apply through the nozzles . Another advantage is that you’re able to incorporate a wider variety of colour and materials in the procedure , including metals and ceramic .

Photopolymerization

Photopolymerization is a 3D printing process technology whereby drop of a liquid plastic are exposed to an ultraviolet laser . During this exposure , the light converts the liquid into a solid . The terminus comes from the roots photo , meaning light and polymer , which describes the chemic composition of the solid plastic .

In the 2000s , the Piedmont Triad Center for Advanced Manufacturing ( PTCAM ) was a partnership of schools and business that provided hand - on training in metalworking skills in North Carolina . Some of PT CAM ’s preparation incorporate a stereolithography apparatus ( SLA ) by 3D Systems . SLA uses photopolymerization , calculate a laser across a value-added tax of liquid plastic called photopolymer . As withinkjet3D printing process , the SLA repeats this physical process layer by bed until the print is finished .

Sintering

Sintering is another additive cook up engineering science that involves melting and fusing particles together to print each successive cross - subdivision of an object . Selective laser sinter ( SLS ) is one form of sintering used in 3D printing . SLS relies on a ultraviolet laser beam to disappear a flame - retardant powdered stuff , which then solidify to constitute the printed layer . This is similar to the mechanism behind 2D printer : They melt the toner so that it will adhere to the paper and create the epitome .

sinter is naturally compatible with building metallic element objects because metallic element manufacturing often expect some case of melting and reshaping . One example of using metallic element as a sintering material is from 3D Systems [ source:3D Systems ] . The aim created with LaserForm A6 have several advantages over metal production made by other agency , such as die - casting . One of the large advantages is the in high spirits level of precision that SLS can achieve .

So far , we ’ve looked at how 3D impression has developed and four wide adopted 3D printing technologies . Next , let ’s examine the general cognitive operation of printing three - dimensional object , which applies no matter what approaching you ’re using .

The 3D Printing Process

No matter which approach a 3D printer expend , the overall printing process is generally the same . In their al-Qur’an " Additive Manufacturing Technologies : Rapid Prototyping to Direct Digital Manufacturing , " Ian Gibson , David W. Rosen and Brent Stucker list the following eight pace in the generic AM process :

The 3D Printing Revolution

increase availability and affordability of 3D printing solutions has made the technology attractive to mass across many manufacture . For example , the automotive industry has used 3D printing technology for many years for speedy prototyping of new auto part designs . The depiction above shows a manifold prototype created by the Piedmont Triad Center for Advanced Manufacturing ( PTCAM ) .

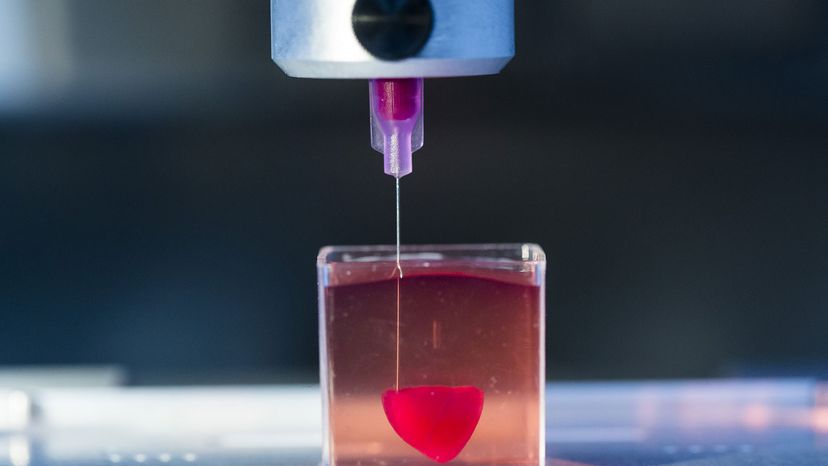

Medical Applications

Themedical professioneagerly adopted 3D printing for a number of USA , such as publish prosthetics . Traditional professionally made prosthetics can be expensive , but a 3D printer could make a prosthetic hand for as minuscule as $ 50 [ source : Amputee Coalition ] . Similarly , Walter Reed Army Medical Center has used 3-D impression to produce models that surgeons can use as a guide for facial reconstructive surgical operation [ source : King ] . Several professional 3D printer manufacturers sell machines specifically designed for dental work .

Aerospace Engineering Applications

Engineers in the aerospace industry incorporate 3D printing to help test and amend its figure as well as to show off how well they work [ reference : Gordon ] . Research company EADS has an even bolder ambition for 3D printing process : to manufacture aircraft parts themselves , including an full annexe for a great plane . EADS researchers see this as a green technology , believing 3D printed wings will reduce an airplane ’s weight and , thus , foreshorten its fuel usage . This could cut carbon - dioxide emission and the airline business around $ 3,000 over the track of a yr . [ source : The Economist ]

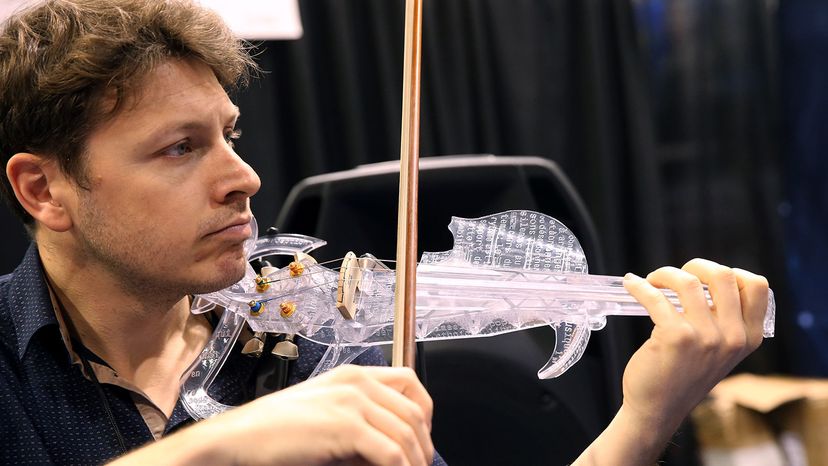

Artistic Applications

3D printing also has some interesting aesthetic applications . interior decorator and artist are using it in creative way to produce art , fashion and article of furniture . Graphic creative person Torolf Sauermannhas created colorful geometric sculpturesusing 3D printing process [ source : Jotero GbR ] .

exemption of Creation ( FOC ) , a troupe in the Netherlands , sold 3D printed products made from laser - sintered polymeric amide , including light with intricate geometric designs and wearable designs dwell of interlocking plastic rings that resemble chain of mountains chain armour . FOC also has a bit of bodied guest using its design and print help , including Philips , Nokia , Nike , Asics , and Hyundai [ source : FOC ] .

Culinary Applications

A tastier practical program of 3D printing technology comes from the deep brown diligence , which has developed machines that can produce unique confectionary item . Although undesirable for aggregate production , 3D printers can make computing machine - design object as prototypes , or just as unequaled , customize treat [ root : Ooi ] .

look for something a little more savory ? you could employ 3D printer to create many type of intellectual nourishment — it has to be something you could strain to get it into the machine — but you could make burgers with 3D printing process . One affair to observe : Printed food has a different texture than traditional solid food [ germ : Houser ] .

The Cost of 3D Printing

Historically , 3D printing has been an expensive technology . PTCAM ’s SLA , described earlier in the clause , cost more than $ 250,000 ; the liquid plastic costs about $ 800 per gallon . Organizations that own this type of equipment might sellstereolithographyservices to others or allow companies to purchase block of time to habituate the equipment .

Today , many large industrial AM machine are still costly , though less so than before . For instance , in September 2019 , 3D Systems ' ProJet CPX 3000MJP 3600 was selling for less than $ 100,000 and could create mannikin in high-pitched definition up to 11.75 inches by 7.3 in by 8 inches ( 298 millimeters by 185 millimetre by 203 millimeter ) [ origin : BasTech ] .

A Waste of Precious Energy?

In addition to damage , there are some other drawbacks with 3D pressman . They expend a lot of energy , about 100 times as much electric energy as regular manufacturing . Researchers also found that they can emit a lot of carcinogenic particles and volatile constituent chemical compound , in particular when used in a modest infinite such as a home .

The plastic used for most 3D labor also has its own job . Plastic remnants from 3D projects likely will terminate up in landfill and contribute to Earth ’s crisis with disposable charge card . Furthermore , plastic ’s strength vary and may not be good for all component parts of a project . 3D printer are also sluggish and a undertaking could take several days or hours to print [ source:3 - D Insider ] .

More Controversial Than Ceramic or Aluminum

It is probable that many of these problem will be remedied over metre , as the technology improves . But other problems may persist . For illustration , people have already made guns using 3D printing machine , include one manwho was denied a shooter licence earlier . Can stairs be take to keep hoi polloi from using 3D printers to make guns , knives and other artillery ?

There is also business concern aboutcopyright usurpation . the great unwashed could get grasp of blueprints and print an object rather than purchasing it from the patent or right of first publication bearer . It may bedifficult for a patent of invention holderto chase after down the person ( or C of people ) who print something patented and claim copyright misdemeanour .

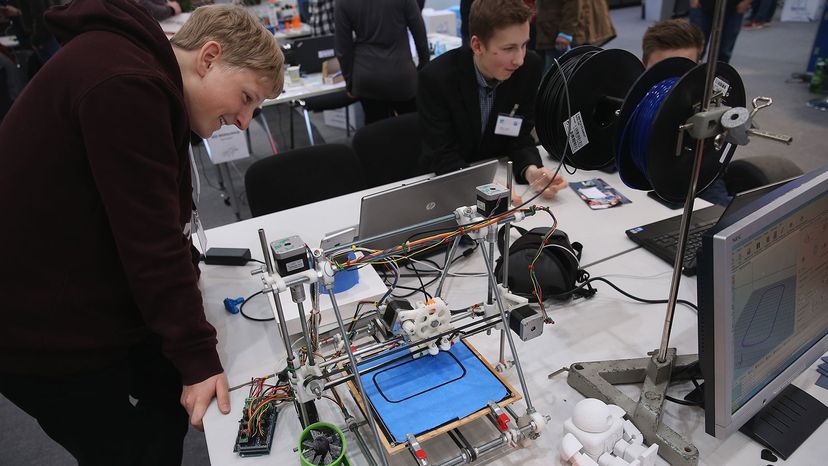

3D Printing at Home

Although it ’s still not commonplace , 3D printers are show up in more home , libraries , schools , and makerspaces . Mary Leontyne Price for these machines have also decreased as the applied science matures . For example , as of 2024 , aMakerBot Replicator Mini+starts at $ 1,375 . The ship’s company sells modest spools of its PLA material in 12 standard and modified - variant colors ( burn - in - the - sinister , anyone ? ) for an surplus charge .

If you do n’t desire to fling on a machine for rest home manipulation , you could always establish one yourself . For example , physicist and bloggerWindell Oskay built his own 3 - D printerin 2007 that fabricates objects from sugar using a sinter approach . The project , called CandyFab , has a consecrated website atCandyFab.org . Although the undertaking has shut down , you’re able to still read about it and how he made it work .

For a more professional approach , you could purchase 3-D printing process services rather . These services allow you to send in your own hound file and get back a high - quality yield of your object or object make by an industrial three-D printer . on-line companies that offer 3D printing services include Shapeways and Ponoko . These sites also give you the option of position up an online store , allowing you to make money when others purchase 3-D print of your design . [ source : Shapeways , Ponoko ]

Although a low - cost variant has yet to come about , 3D printing continues to offer better print timber at a cheesy price . Perhaps in the time to come these machines will be commonplace tools used to remedy everyday problems like printing a new star sign - key instead of drive to the hardware store for a renewal .