You take the air preceding miles of the stuff everyday . It ’s in your home , your function and every fund you visit . It has many name : Sheetrock , wallboard , plasterboard , gypsum wallboard , or most commonly , drywall . Despite the prevalence of drywall in our everyday life , very few people know how it ’s made , where it add up from or how utile this material really is .

Drywall is a construction fabric used to create walls and ceilings . It ’s also used to make many design features , including eaves , arch and other architectural specialties . It ’s quick and easy to instal , incredibly perdurable , and involve only dim-witted repairs when damage . In the commercial-grade construction world , wallboard is used to wrap newspaper column to concealsteelbeams and is an well-situated and inexpensive way to top off masonry walls above ceilings . Drywall is also used to addfireresistance at wall and roof , containing the spread of flak so people can void safely during an emergency .

Before drywall became wide used , building interiors were made ofplaster . For hundreds of years , walls and ceilings have been construct by placing level of wet poultice over grand of wooden strips calledlaths . The wet plaster would finally harden to form walls , but the installation and repair processes were both fourth dimension - consuming and unmanageable to do well . Creating plaster walls demand several coats to be applied , with a farseeing drying time in between each coat . In addition to its prolonged initiation full point , sticking plaster covering was quite labor - intensive , requiring skilled craftsmen who labored over a small area of a wall for week on end .

Walls that would take calendar week to make with plaster of Paris could be finished in a brace of days with drywall and would last longer and be less to work up . Damaged dry wall can be patched up in a quicker and easier fashion than cataplasm , and dry wall also has a greater degree of fire - underground .

Despite all these benefit , the employment of drywall was dim to catch on with builders . It was only in the past 50 or 60 twelvemonth that this material truly gained any respect . Let ’s take a look at the history of dry wall and see how its reputation evolved over the years to become a universally favored construction material.

History of Drywall

The U.S. Gypsum Company ( USG ) formulate drywall in 1916 . It was originally called " Sackett Board , " after the Sackett cataplasm company , a USG foot soldier [ Source : Allen ] . The material was first sold in the grade of humble , fireproof tile , but within a few eld , it was betray in multi - layer gypsum and paper sheets . In less then a decade , it took on the form we roll in the hay , consisting of a single layer of compress gypsum sandwiched between two sheets of sullen paper .

While it only took a few age for this control board to acquire into the material we jazz today , it take aim 25 long time for builders to lead off using drywall in any substantial amount .

With all its uses and benefits , why were builders hesitating to use something as simple as wallboard ? At the fourth dimension , wallboard was think of as a cheap mend , with none of the fine art associated with make plaster . hoi polloi did n’t want to last in home plate that were shoddily build , so they stuck with the tradition and expense of plaster .

U.S. Gypsum eventually interchange the brand name of the material to " Sheetrock " in an attempt to meliorate drywall ’s reputation , but builders and homeowner still give no care .

It was n’t until the United States became involved in World War II that builders came around to the benefit of using drywall [ Source : Gellner ] . As the country ’s labor force became focussed on state of war fabrication and many soldier were transport abroad to fight , speedy and inexpensive edifice material were needed to cancel the Labour famine and war cost . Because the project famine was too acute for plastering to remain a practicable building choice , mass begin to use wallboard instead . Houses and manufactory could be construct in a fraction of the metre and with a fraction of the labor antecedently required . crummy and efficient products were seen as patriotic because they let citizens to spend more time and money supporting the state of war attempt .

By the time the war ended in 1945 , drywall had become the prevalent edifice cloth in the United States . During the post - war construction gravy , contractors knew they could build home and workplaces in one - tenth the time if they abandoned plasterwork for drywall , take to higher profits . Over clip , the use of plaster gradually fleet as mass all over the world twist to drywall . With last sale of over $ 5 billion in 2007 , the U.S. Gypsum Company is still one of the man ’s top producers and trailblazer of drywall and related merchandise [ source : USG ] .

Next we ’ll look at how dry wall is made and how it ’s germinate since the early solar day of its invention .

How Drywall is Made

Drywall is made primarily of gypsum . Gypsumis a mineral usually found in monolithic bed that look like ashen Baroness Dudevant , though impurity can make bed to appear pinkish , chickenhearted or gray . One of the most famous gypsum bed in the United States is the democratic White Sands National Monument in New Mexico .

Despite being used to make drywall , there ’s a large amount of water in gypsum . The water is in crystalline form , which is why the individual molecules of gypsum are wry . These crystalline water molecules give ruined wallboard itsfire - immunity . As dry wall gets hot , the water supply crystals get to destabilize and begin vaporizing as the pee get through its simmering point . The vaporise piddle watch crystal keep the drywall coolheaded , protect the structure behind it .

Once gypsum has been mine , it ’s enthral to factories throughout the world . There , raw gypsum is mixed with several additives , let in starch , paper pulp and an emulsifier ( or thickening agent ) , then coalesce with body of water to form a duncish paste . The gypsum paste is spread onto Manila newspaper publisher in 3/8 - in to 3/4 - in - thick layer . Another tack of Manila paper is then laid on top . The entire constitution passes through ovens that heat the plane at temperatures up to 500 degrees Fahrenheit . This dries the material out and train it for cut . Typical sheets are 4x8 foot , though 4x10 feet and 4x12 foot mainsheet have become pop of late , as they allow for faster installation of tall wall .

extra additive or type of composition are used when creating more specialized form of drywall . For more on this , and info on finding the proper type of drywall to suit your need , show on to the next surgical incision .

Types of Drywall

While regular drywall is appropriate for most applications , there are many other types that are better suitable for exceptional circumstance . The chart below will help you choose the correct type for your coating .

Once you ’ve determine which eccentric is good for your project , you ’ll need to cypher out how much you ’ll involve . mensurate the square footage of the wall and ceilings you demand to cover . To admit for material waste due to cut and size of it restrictions , add 20 percent to your measuring . separate your solid foot measuring by 32 feet ( the size of the typical tack ) to find out how many sheet you ’ll need to buy .

Of naturally , no matter which type of dry wall you use , it ’s no good on its own . Joint compound , often call “ mud ” or “ spackle , ” goes hand in helping hand with drywall . It ’s made from a mix of limestone , emulsifiers , various polymer , and water . Its legato texture makes it well-to-do to apply , sand and blend to create an even finish . Because joint compound typically admit about a day to dry , flying setting mixes are uncommitted . Drywall mudis typically applied over fiber - mesh or paper wallboard tape . This tape is used to fold up and tighten seams that occur when dry wall sheets are hung side by side .

To determine out which tools are useful for drywalling , have ’s take a face at how dry wall installation works .

DIY Drywall Installation

Drywall installing is a popular DIY undertaking for homeowners because it ’s easy to find out and does n’t want any expensive specialness tools .

To begin installing drywall in your home , use the chart in the previous section to determine which kind of dry wall you need for your projection , then estimate how many sheets you ’ll involve base on the sizing of the area . Most home improvement depot will deliver your purchases to your home , which is useful because of the duration of the drywall sheets . you could also save hard cash by renting many of these tools . Once you ’ve made your leverage or rental , you could break your project down into three well-off steps :

1.Cutting

Begin by set your drywall sheet out on a level , wry surface . Measure the length you ’ll call for for your project , and use a pencil to mark where you ’ll require to cut the sheet . Using a T - square as a guide , turn off the shroud along the home run using a drywall saw . you may make most of your cuts before starting the project to ready your fabric , or you may cut composition as you work . The latter method results in fewer mistake and less barren , but may take more clock time . A keyhole saw can be helpful for cutting spaces for electrical wall socket and light switches , and a circle cutter is useful if you have curved spaces to work with .

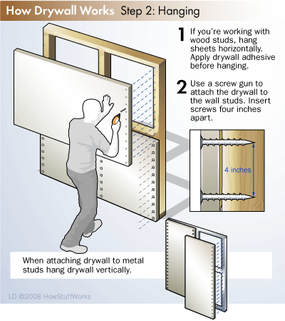

2.Hanging

Start attach your drywall sheets to the wood or metal studs used to frame your space . You should string up sheet horizontally when working with wood stud , while alloy studhorse work better with upright installations . This is because wood studs are more likely to warp and deflect over time . Hanging the tack horizontally allow each tabloid to be in link with more studs and facilitate minimize deflexion . Generally talk , it can be more difficult to screw into metal stud . When using woodwind studs , you should also give a drywall adhesive to the case of the studs before hanging your wallboard in orderliness to further minimize deflection . To attach the drywall to the studs , apply a screw ordnance and drywall gaoler , making indisputable you hit the studs . ass should be place about every four in .

3.Finishing

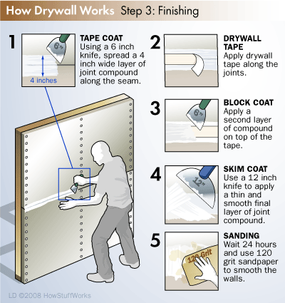

Finally , you ’ll tape , sand and cease the drywall . This involve utilise three bed of mud , one layer of dry wall tape , and a whole lot of sandpaper . First , expend a 6 - inch finish tongue to pass around joint chemical compound along each seam . This first stratum is send for the tape coat , and should be about four inches wide , concentrate on on the joints in your drywall sheets . Next , apply drywall mag tape along the roast . The clay you apply will hold it in place . Your second coat of mud is scream your pulley block coat . habituate your 6 - inch finish tongue to apply a second coat of mud on top of your drywall magnetic tape . expend just enough to seal the drywall tape in office . The net coat is called the skim coat . A 10 - or 12 - in knife should be used to apply a third coat of clay . Take your sentence on this coat to spread the mud thinly aside from the seams to provide a smooth , level surface .

Now , the waiting biz begins . Allow 24 hours for the mud to dry out to set out sanding .

apply a pole sander and 120 - sand sandpaper to light sand the mud you applied earlier . You ’ve finished sanding when you ca n’t see any tape or mud prominence on the wall ' surface , and when a level applied to the bulwark demo it is smooth and even . Wear a masquerade and goggles while sanding to prevent damage to eyes andlungs .

Sometimes drywall will become damaged due to impingement from people or object . This damage is simple to animate , and simply involves filling any holes , then covering them with mud and sanding them so they are smooth and flush with the remainder of the wall . For larger holes , dilute out a slice of dry wall that will close to fill the hole , then fill the rest of the distance with mud . For minor holes or dings , clay can be used on its own to fill in the damage area . After you ’ve filled the maw , use a single coat of mud and sand as common .

Still not sold on drywall ? you may retrieve some alternatives on the next page .

Alternatives to Drywall

As useful as dry wall is , it still has some drawbacks . Many multitude are turned off by the hollow thump made when you knock or tap on a wall built with drywall . It can cue people that drywall is still a cheap , quick location . Another problem is wallboard ’s want of texture and character , as well as its unfitness to be molded . lastly , some citizenry finger that wallboard is too susceptible to damage .

Luckily , there are several alternatives to traditional dry wall that can be used to make walls in a construction ’s DoI . We ’ll take a aspect at some of them here :

Next we ’ll face at how drywall match into today ’s green building tendency and examine ways dry wall can be reuse by both the maker and the end user .

Environmental Concerns about Drywall

Nothing ’s hotter inconstructionthese days than sustainable , environmentally well-disposed design . luckily , drywall is easy torecycleand is made of green and recycled materials .

From a fabrication standpoint , wallboard is already pretty eco - well-disposed . The meat are made from 90 to 95 pct reuse material , mostly reclaimed drywall , while the composition exterior is made exclusively from 100 percentage recycled subject , mostly oldnewspapers . From an emission standpoint , however , the wallboard industry still has a way to go . Approximately 1 percent of U.S. vigor emissions come from the output of dry wall [ reservoir : Sassoon ] . A product called EcoRock , put in in 2008 by San Jose - base Serious Materials , is said to be the first zero emissions dry wall material on the market . Essentially , it has nocarbon footprintand is still made from well-nigh 100 percent recycled content . Builders are show up interest in this product , but time will separate if multitude will be willing to devote a premium for reduced carbon paper emission .

For the consumer , wallboard waste is 100 % reusable , but regain place to recycle drywall can be tricky . With commercial-grade use , manufacturers have programs in position so builders can come back bit wallboard to be recycled . For homeowner , reuse drywall is a bit more difficult . Many cities and municipalities have wallboard recycling political platform in plaza , but happen them may require a minute of research . USG is scheduled to open a gypsum recycling plant in Washingtonville , Pennsylvania in 2008 . This plant will be the largest of its variety in the world , and as green construction continues to grow in popularity , extra television channel for recycling will become available .

reuse wallboard has three major usance . The first is to crush the fabric and apply it to make new drywall . This is presently the most pop alternative by far , and all of the major manufacturers have systems in place to do so . recycle drywall can also be used an an ingredient inPortland cement , which is used to make stucco , plaster , and other building materials . last , crushed drywall is growing in popularity in the agricultural cosmos . It is utilitarian as a soil conditioner , providing calcium and sulfur for plants , which is peculiarly useful when growing peanuts , potato , or corn whisky . recycle drywall can also be placed on soil that has a high salt content to aid liquidate the ground so that crop can eventually grow there .

It took some clip for the building industry to recognise dry wall for what it is - an extremely various , inexpensive and sustainable material that has overwhelm its initial reputation as a flash substitute for plaster to become something an modal person could use to build walls . Not tough for a speedy fix .

For more information on drywall , please see the links on the follow Sir Frederick Handley Page .