Stereolithography , also known as 3D layering or3D printing , allow you to create upstanding , plastic , three - dimensional ( 3D ) objects from computer - aided purpose ( CAD ) drawings in a issue of hour .

Whether you are a mechanical engineer wanting to aver the fit of a part or an inventor look to create a plastic epitome of an innovation , stereolithography give you a fast , comfortable way to work dog drawings into material objects .

3D impression is an first-class example of the age in which we live . In the past , it could conceivably take months to prototype a part ; today , rapid prototyping can take place over mere hours , and with astoundingly running mechanical attribute .

Read on as we take a tour of the stereolithography service bureau at PT CAM ( Piedmont Triad Center for Advanced Manufacturing ) so that you’re able to understand everything regard and see some actual 3-D models that this technology can produce .

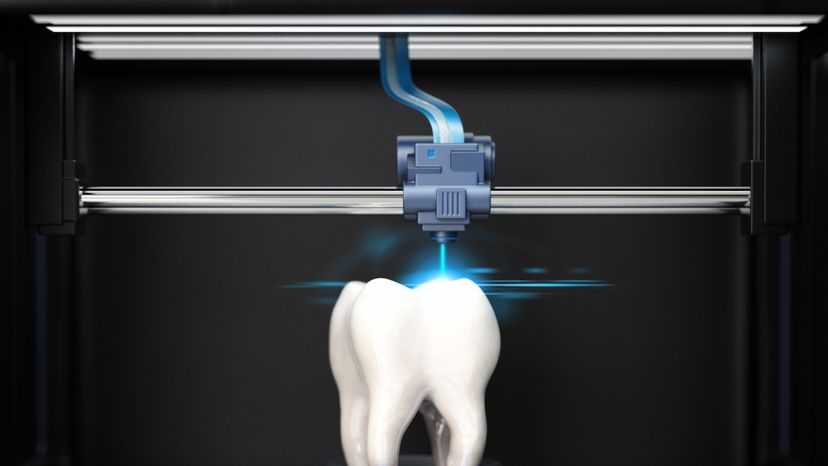

The Stereolithography Machine

PT CAM utilize a stereolithography machine bring forth by3D Systems . This political machine has four authoritative part :

The photopolymer is sensitive to ultraviolet Christ Within , so when the optical maser touches the photopolymer , the polymer hardens . If you stand next to the stereolithograph apparatus ( SLA ) , you may in reality see the laser as it builds each level .

SLA Materials

A few elementary materials include light-sensitive polymers and support structure , which endure overhanging characteristic but do not top the Emily Post - processing . Secondary and specialized material are gamy heat deflection and in high spirits - temperature rosin , both of which can hold up high heat deflexion temperatures , and flexible and long-wearing resins fit for bow and flex .

The Stereolithography Process

The inwardness of SLA printing involves a optical maser radio beam precisely directed by a lightly - emitting twist to cure the polymer rosin in a resin cooler . The SLA printing process become something like this :

This is not a particularly quick unconscious process . Depending on the size of it and number of objects being created , the laser might take a minute of arc or two for each layer . A typical run might take 6 to 12 hours . Runs over several twenty-four hours are possible for large physical object ( maximal size for the relatively previous machine shown above is an object 10 inch , or 25 centimetre , in three property ) .

You set about by creating a 3D aim for your object in a CAD program . This pattern is tweaked before building with support that raise it up off the tray slimly and with any internal brace that is require during building . The SLA then renders the aim automatically ( and unattended ) .

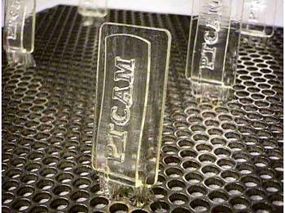

When the process is staring , the SLA raises the platform and you end up with your 3D object . If the physical object is small , you could produce several of them simultaneously if you like . They all sit next to each other on the tray .

The following photo show a tray after building is complete , with several identical object raise simultaneously :

Once the run is complete , you rinse the objects with a solvent and then " bake " them in an ultraviolet oven that thoroughly cures the charge card .

Advantages of Using SLA Technology

SLA technology offers several benefits over traditional manufacture methods like injection moulding and meld deposition modelling . It is equal to of producing parts with suave control surface polish , o.k. features , and gamy complexity without the need for multiple tools or molds .

What You Can Create with Stereolithography

Stereolithography grant you to create almost any 3D shape you may imagine . If you’re able to get it into a CAD program , you’re able to probably make it . The only caution is the need for structural wholeness during the building procedure . In some display case , you need to add inner brace to a design so that it does not collapse during the printing or curing phases .

The photo on this Thomas Nelson Page evince you a typical physical object that was created at PT CAM . The piece is lightweight and has the strength of polystyrene plastic . Since you may climb up and drill pieces , you may try it out in real manipulation .

For example , a chair manufacturer will create dissimilar armrest shapes using stereolithography and try them out on existent chairs to see how they palpate .

Costs of Stereolithography

Stereolithography is not an inexpensive cognitive process . The machines once be in excess of $ 250,000 and still get up to ten-spot of thousands of dollars ( but you could find desktop SLA pressman for much less ) . You also call for to ventilate them because of the fumes the polymer and the dissolving agent create .

The polymer is extremely expensive as well . CibaTool SL5170 resin , a common photopolymer used in stereolithography , cost about $ 800 / gal when we visited PT CAM . For these reasons , it is rare to find professional stereolithography machine anywhere but in large ship’s company .

However , there are religious service bureaus that can make the advantages of stereolithography available to smaller shops and individual . It ’s still not cheap , but compared to purchasing your own SLA and rosin or having parts machined , it is a veridical steal .

Special thanks to Joel Leonard , Jerry Watkins and Steve Oneyear for their supporter in create this clause !

We update this article in conjunction with AI technology , then made indisputable it was fact - checked and edit by a HowStuffWorks editor in chief .