Small gas engines serve us in many ways . They power lawn mowers , tillers , cultivators , trimmer , edgers , snowblowers , chain saws , pumps , generators , tune compressor , and other useful house tools . They also power our fun : outboard boats , snowmobiles , motorcycles , all - terrain vehicle , ultralight aircraft , and other toys . To keep them operating expeditiously , an proprietor of these tools and toys should know about minuscule engine : how they work and what to do when they do n’t .

pocket-sized gas engine are made up of individual organization that crop together to produce power . Each organization has many components . inner burning petrol - power engines require six system : fuel , exhaust fumes , lighting , burning , cooling , and lubrication . In this clause , we will discuss the system and component that make small locomotive work .

Fuel and Exhaust

The fuel and exhaust systems are vital to operation . They furnish the fuel for burning and remove exhaust gas . The come after are component of a fuel and exhaust system .

petrol : petrol is a combustible liquid state that burns relatively slowly . However , when sprayed as a mist and sundry with air travel , it is quite volatile . All it needs is a spark . Two - fortuity engines require that oil be mixed with the gas to lubricate inner part . Four - cerebrovascular accident engine apply a fuel - air mixture .

Fuel Tank : The fuel tank car stores fuel in training for mix by the carburetor and use by the engine . Some fuel tanks are pressurize with air to aid present fuel to the carburetor . Other armored combat vehicle are non - pressurized and depend on a fuel pump to deliver fuel to the carburettor .

Fuel Line : Fuel is move from the tank to the pump and/or carburetor through a fuel line . pressurise fuel systems often have a squeeze incandescent lamp in the fuel line of products for construction pressure .

Filter : A carburetor jet has a small opening that can easily become clogged . A fuel filter traps dirt and sediment from the gas before it is delivered to the carburettor .

Pump : A fuel heart produces a void that pulls the fuel from an unpressurized armoured combat vehicle , then fork over it to the carburettor .

Carburetor : The carburetor has one job : to mix the correct proportion of gasoline and air for the engine . Too much petrol in the mixture make it rich ; too trivial gas makes it lean .

Throttle : The throttle master the amount of fuel - air mix that enter the engine from the carburettor . The gas pedal thus assure the speed of the engine .

Primer : A primer coat injects a little amount of gas into the carburettor pharynx to make the initial fuel - air mixed bag rich . A primer is used to help oneself commence a cold engine .

Choke : Some engines control the mellowness of the fuel - air mixture at inauguration by controlling the air rather than the fuel . A choke reduces the amount of air in the fuel - line miscellanea .

Governor : A governor is a gadget that mechanically opens the locomotive engine ’s accelerator when more power is involve and close it when the load is light .

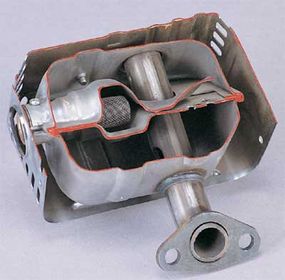

Muffler : Small gas engine , especially two - stroke engine , are noisy when they lock . A muffler reduces the sound of the exhaust system gases by elapse them through baffle board .

Spark Arrestor : A spark can exit the exhaust fumes port of a small gas engine , potentially part a fire on nearby combustibles . A spark arrestor on the exhaust port can repress the opportunity of such a flaming . electric arc arrestors are especially of import on chain saws , motorcycles , and all - terrain vehicles operated in dry forest .

Ignition

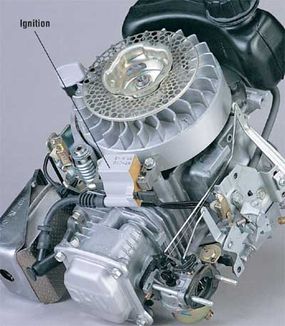

The inflammation is a master system within all small flatulency engine . It produces and render the high - voltage spark that ignites the fuel - air mixture to do burning . No spark means no burning , which signify your railway locomotive does n’t run . Below are the components happen in small engine ignition systems . Some systems will admit breaker pointedness ignitions while others calculate on hearty - state lighting .

Magneto - Powered Ignition System : A magnetoelectric machine uses magnetism to render electricity in firing where there is no battery . The magnetoelectric machine is turned by the crankshaft , which rotates when the manual recoil starter is pulled . The three types of magneto kindling systems are mechanical - surf , condenser - discharge , and junction transistor - control .

electric battery - Powered Ignition System : If your small engine includes a battery for starting , theignition coilwill also utilize it to furnish spark to the electric discharge plug . A battery stores electrical energy until needed . Battery ignition systems also use mechanically skillful - breaker , capacitor - spark , and junction transistor - moderate ignitions .

Mechanical - Breaker Ignitions : High - voltage electricity must be sent to the spark plug at the appropriate time . In mechanically skillful - surf ignitions , this problem is performed through the contact points and a condenser .

point : As the crankshaft rotates , a River Cam opens and closes a set of link points . These points function as an on / off shift : Closed is on , and open is off .

Condenser : Because the spark moving across decimal point can damage their surfaces , the condenser stores electric potential to reduce arc between point .

Capacitor - Discharge Ignitions ( CDI):A electrical condenser is a large condenser . A CDI stores and drive home voltage to the coil using magnets , junction rectifier , and a capacitor

Transistor - Controlled Ignitions ( TCI):Transistors are electronic controllers . A TCI uses transistor , resistors , and diodes to control the timing of the spark .

Coil : An ignition curl is simply two coils of wire enwrap around an atomic number 26 core . The curl changes low voltage ( 6 or 12 volts ) into the high potential difference ( 15,000 to 30,000 volts ) require by the spark sparking plug .

Spark Plug : A sparkle chaw is an insulated electrode that is screwed into the top of the locomotive engine cylinder . High - emf time electricity from the magneto travel by wire to the arc nag . The base of the plug has an melody gap of about 0.030 inch ( 30 thousandth of an inch ) , which the current must jump .

Wires : The main wire from the coil to the breaker full point and lowly conducting wire from the coil to the Muriel Sarah Spark plug(s ) deliver electrical energy to the ignition components .

Distributor : A distributor is an lighting system of rules for engine with more than one cylinder and spark plug . It distributes the glint to the appropriate piston chamber using a rotor , cap , and individual light plug wires .

Combustion

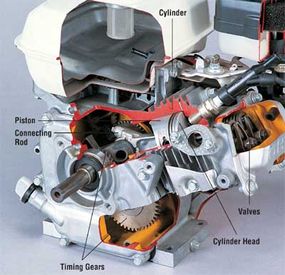

The burning system of a belittled gas engine is where the work gets done . Components of the combustion system let in the cylinder block , piston chamber head , camshaft , valves , Walter Piston , connecting rod , crankshaft , timing gear , and flywheel . To well understand lowly natural gas engine , let ’s see at how this vital system works .

Cylinder Block : The largest single part in a small natural gas engine is the cylinder pulley-block . It is a patch of metal in which the piston chamber mess is bored or placed .

Cylinder Head : The piston chamber head is the top , or ceiling , of the cylinder and is sequester to the block with bolts . look on the case of engine , the oral sex may or may not include valve .

Piston : A piston is the movable trading floor in the combustion chamber . Its up movement squeeze the fuel - airwave concoction . After burning , its down movement rotates the crankshaft .

Crankshaft : An engine ’s crankshaft is a alloy shaft with an offset section onto which the connecting perch is tie . Rotation of the crankshaft move the plunger up in the piston chamber . Movement of the plunger down in the piston chamber then revolve the crankshaft .

Connecting Rod : Between the plunger and the crankshaft is a connecting rod . At the prominent ending of the connect rod is a posture that allows rotation around the propel crankshaft . The small end is attach to the piston thole .

Valves : Valves simply open up and tightlipped passing . A reed valve in a two - stroke locomotive engine is activated by changes in air air pressure .

Flywheel : At the end of the crankshaft is a round weight wheel called a flywheel . The flywheel present the engine ’s baron to devices ( cycle , steel , etc . ) and helps keep the crankshaft turning smoothly .

Small Engine Image Gallery

Cooling and Lubrication

Combustion and friction get heat . Heat and friction – if not see – can quickly damage an engine ’s components . Small flatulency engines are typically cooled by atmosphere . Friction is slim down using transportable bearings and lubricating substance .

melodic line - Cooling Fins : For simplicity , most smaller gas engines are cool by air . metallic element fin around the outside of the burning sleeping accommodation help dissipate the intimate heating .

Friction : Friction is resistance that come about when one surface rubs against another . detrition make vesture . In an engine with many moving part , detrition is reduced with bearings and lubricating substance .

Bearings : A bearing is a replaceable part that takes the brunt of the rubbing . A rubbing bearing relies on lubricating substance to denigrate friction . A nonfriction charge uses operose steel rollers or balls to prevent wear , though it too requires some lubrication .

lube : lube such as oil and filth reduce airfoil rubbing by cake part with a plastic film . lube in two - CVA engines are applied to surface by mixing crude with fuel .

viscousness : An oil ’s viscosity is its electric resistance to flow . The thicker a lubricating crude oil or grease is , the in high spirits its viscosity number .

Filters : Friction bump . move part wear , even with the best lubricants . The result metal as well as carbon from the combustion cognitive operation must be clean from the oil to ensure long lubrication . Some small engine use crude filter to absent contamination from the circulating oil .

Regularly service your small locomotive engine will ultimately save you money and time . In the next section , we ’ll review how , where , and when to service this locomotive engine .

The Benefits of Regular Small-Engine Maintenance

Benefits of Regular Service

Servicing your small locomotive tool or miniature on a even basis offers many advantages over the hold back - Until - It - Breaks Maintenance Program .

How , Where , and When to ServiceKnowing how to serve is as important as roll in the hay when . Some Robert William Service procedures can be performed wherever you put in your puppet or toy : in a garage , store shed , or tool shed . If the unit is heavy , you may make a ramp up to a sturdy table that is at a handy height for act upon . Or you’re able to employ a ratchet winch to raise the locomotive engine . Units count less than 40 pounds may be elevate to a workbench or mesa as long as you lift with your legs rather than with your back . Get help if you require it , and make indisputable that the unit will remain sturdily in place as you serve it . Remember to always put base hit first!Servicing a lowly engine is loose once you have it off what to do and when to do it . A overhaul chart can facilitate you make up one’s mind common table service requirement as well as tag what Robert William Service has been done . Your locomotive - powered social unit may have a service chart in the possessor ’s manual or service manual . Typical recommendations include changing engine oil every 25 hours of use and tuning up the locomotive engine at least once a yr . The purpose of ongoing service , also known as preventative maintenance , is to keep your locomotive - driven tool or plaything in good operating condition . Ongoing service procedures include atmosphere neat service , crankcase breath service , cool organisation service , muffler service , lubrication , and tune - up . Lubrication inspection and repair means making certain that all moving parts have sufficient lubrication ( oil and/or grease ) to denigrate wear . Lubrication service subprogram include mixing oil with fuel in two - stroke locomotive , and lubricate other moving parts . A tune - up consist of the modification and/or replacement of part decisive to smooth and efficient railway locomotive operation . Those function include components in all engine organization : fuel , exhaust , ignition , burning , cooling , and lubrication . inflammation tune - ups are more authoritative for mechanical - circuit breaker kindling than they are for ego - contained upstanding - state ignitions . veritable tune - ups will keep your little railway locomotive running swimmingly and reduce the pauperization for repairs . In addition , you should check other organisation and make adjustments as need to keep them operating smoothly . This includes conform the throttle , exit , and regulator gene linkage , and houseclean off debris . Engine - drive peter and toys commonly come with an possessor ’s manual of arms . While some manufacturers ' manuals are more staring and better compose than others , most manuals let in basic information on safe operation and service . regrettably , product manuals are often write to lose weight the manufacturer ’s liability for accidental abuse rather than to help the possessor service the product . In addition , manual for railway locomotive - drive production typically show how to serve the nonengine components : the forage backstop , wheel adjustments , blades , concatenation , and other parts . servicing information for the engine may be minimum or nonexistent in the owner ’s manual of arms .

What can you do about this lack of data ? Fortunately , there are numerous after - market publishers of service manual for specific models of small engines . If you do n’t have an possessor ’s manual of arms , you could get in touch with the manufacturing business instantly to purchase one ; producer also sell service manuals . Most producer keep product manuals for up to 20 years . If they only have one original copy will , you’re able to often request a photocopy for a little charge .

Knowing how to serve the fuel organisation is an authoritative part of care for a small railway locomotive . Learn how to care for fuel filters , carburetors , and other major fuel system part in the next incision .

How to Repair a Small-Engine Fuel System

The function of a small engine fuel system of rules is to store and fork out fuel to the burning chamber . Maintaining a fuel system includes servicing the fuel filter , air cleaner , fuel army tank , and fuel lines ; adapt the carburettor ; and adjusting the governor . Of of course , not all small engines have all of these components .

Servicing Fuel Filters

Some small railway locomotive have a fuel strainer in the bottom of the fuel tank . Others have a removable fuel strainer in the fuel line . Still other lowly engines apply disposable in - bank line fuel filters made of pleated paper . To houseclean deposit from a tank :

dance step 1 : Drain or syphon all fuel from the tank .

stone’s throw 2 : With a flashlight , find the lowest point in the tank : the sediment man-made lake . Clean all sediment from the reservoir roughness .

stone’s throw 3 : pass over deposit from the goal of the filter element .

stair 4 : Wipe the interior of the tank with a clean rag week .

measure 5 : replenish the fuel tankful .

Here is how to houseclean deposit from a fuel strainer :

Step 1 : Find and conclude the shutoff valve on the fuel line .

Step 2 : Loosen the lock chamber nut on the arena retainer and remove the deposit bowlful .

stone’s throw 3 : Empty and clean the deposit bowl . Clean the filter sieve . replenish the deposit bowling ball with fresh fuel .

footstep 4 : Reinstall the sediment bowling ball and trough retainer , tightening the lock nut .

footmark 5 : enter the shutoff valve .

Here is how to replace an in - line fuel filter :

dance step 1 : Find and close up the shutoff valve on the fuel line or use a clothespin to pinch the fuel line closed .

stone’s throw 2 : unplug the fuel filter from the fuel line .

Step 3 : Replace the in - logical argument fuel filter with an precise replacement part .

stair 4 : launch the shutoff valve .

Servicing Air Cleaners

The use of an air cleansing agent on a small engine is to keep turgid molecule in the air from choke the carburetor . The two types of melodic line cleaners used on modest locomotive engine are oil bathing tub and dry . Hereis how to service an airwave cleanser :

Step 1 : Remove the natural covering of the air cleaner , typically by unscrewing a bollock on top of the cleansing agent .

Step 2 : If it ’s an oil cleaner , remove all oil and contaminants from the middle canal of the cleaner , wipe it clean , then replace oil color to the indicated level . A dry cleaner can not be cleaned and therefore must be replaced .

Step 3 : Replace the air fair cover and make certain all fasteners are securely tightened .

Servicing Fuel Tanks and Lines

Fuel system of rules with pumps utilise nonpressurized fuel tank . Outboard railway locomotive typically use pressurized tanks . Fuel lines are usually made of neoprene . Here ’s how to serve a fuel tank and telephone line :

tone 1 : Remove the cap from the fuel tank .

Step 2 : Using a torch , check for sediment in the fuel tank car . If sediment is found , clean the cooler and supervene upon the fuel . substitute the fuel cap when done .

Step 3 : ensure the fuel line and siphon electric-light bulb , if there is one , by coerce them and inspecting for cracks . If damage , replace with a line or a bulb of the same inside diameter . check that it is approve for utilization with fuel .

Adjusting Carburetors

A carburetor mixes fuel and air in the right proportionality for use of goods and services by the locomotive engine . The three type of carburetors commonly used in small engines are natural draft , updraft , and downdraft . These name key the commission that air travel flows from the inlet to the engine manifold paper . To maintain your small locomotive , you will require to make indisputable the carburettor ’s speed and mixture are correctly adjusted .

There are many eccentric and models of carburetors used on little gas engines . Some have more available adjustments than others . Depending on the design , some carburetors are set up at the factory and do n’t let in adjust screws . For exercise , a carburetor may allow modification of high speed , idle hurrying , and out of work smorgasbord while another only leave gamey and jobless pep pill adjustments . Here ’s how to aline the typical three - readjustment carburetor :

Step 1 : With the engine execute , unfold the throttle broad . bend the high - speed adjustment needle forrader and backward until the gamey speed setting is found .

whole tone 2 : Move the gas to the slowest running speed . Adjust the idle - speed phonograph needle until the urge idle speed is receive .

Step 3 : Once the dead f number has been set , align the idle mixture until the engine run swimmingly .

Adjusting Governors

A governor is a twist that controls the speed of the engine as the incumbrance variety . As the load retard the locomotive down , the governor unfold the throttle to return the engine to a fit focal ratio . Governors are usually used on engine - powered electrical generators where constant speed is important . Two types of regulator are instal on small engines : mechanical and air travel - vane .

Caution : An incorrectly adjusted regulator can cause the minuscule engine to manoeuver at too high upper and damage or ruin it .

Unfortunately , there is no general accommodation chronological sequence for lowly engine regulator . Much look on the type of governor , whether the crankshaft is horizontal or vertical , the complexness and pivot points of the gene linkage , and the intended operating range . Because of these factors , refer to an proprietor ’s manual or armed service manual for your specific engine and covering to adjust the regulator .

In the next section , learn how the ignition arrangement needs to be routinely serviced so it can redeem a high - voltage Dame Muriel Spark to help oneself part a small locomotive engine .

How to Repair a Small-Engine Ignition System

An ignition scheme in a small locomotive produce and deliver the gamy - electromotive force sparkle that ignites the fuel - air mixture to cause the burning . Some pocket-sized engines need a battery to provide electrical power and the ignition Dame Muriel Spark . Others develop the ignition system spark using a magnetoelectric machine .

A small locomotive engine ignition includes the ignition accountant ( mechanical - breaker , capacitor - discharge , or transistor - contain ) , spark plugs , flywheel , and wiring . service the ignition system of your little locomotive depend on which types of components it has . Below are step - by - step instructions for servicing ignition systems found in modern lowly engines .

Servicing Nonbattery Ignition Systems

A magneto go for magnetic attraction to supply electrical energy in ignitions where there is no battery . The magneto is become by the crankshaft , which rotate when the manual recoil newbie is pull . Here ’s how to service a non - battery ignition organisation :

whole step 1 : serve magnetoelectric machine .

whole step 2 : avail ignition comptroller .

dance step 3 : Service spark plug(s ) .

footstep 4 : Service flywheel .

If you ask to service a magnetoelectric machine , utilize the following directions :

whole step 1 : Remove the magneto jacket crown and clean surfaces with a small , sportsmanlike paintbrush . pass over any excess crude away .

stone’s throw 2 : Service the ignition accountant ( mechanically skillful - ledgeman , capacitor - discharge , or transistor - controlled ) as report at the bottom of this page .

Servicing Battery Ignition Systems

A battery is a gimmick hold in electrical cells that make and store unmediated current . Batteries used to start and operate low engines typically put in 6 volts or 12 volt . Here ’s how to serve a battery ignition organisation :

Step 1 : Robert William Service battery and charging organisation .

If you are interested in servicing a battery and charging arrangement , here ’s how :

whole step 1 : Use a voltage quizzer to assert that the battery is storing sufficient potential difference . Each cell develop just about 2 volts ( 1.9 to 2.1 volts ) . A 6 - volt stamp battery testing crushed than 5.7 volts or a 12 - volt battery lower than 11.4 volt should be recharged to rated emf or high .

Step 2 : If the battery is conventional ( has three or six caps on top ) , use a gravimeter to check the density of the liquid electrolyte in each cadre . The density or specific gravity should be between 1.26 and 1.28 at room temperature .

If it ’s below 1.25 , recharge the battery . The difference in specific gravity between any two cell should be no more than 0.05 . mark that a sealed sustenance - free bombardment can not be tested in this direction .

footfall 3 : Clean bombardment terminal using a diminished amount of baking soda and a stiff telegram brush . Clean battery cables the same way .

whole tone 4 : audit the cable insularity for erosion and happy chance ; replace as needed .

Servicing Mechanical-Breaker Ignitions

For many years , mechanical - circuit breaker ignition system were the most democratic of all inflammation systems . The high emf electrical energy from the coil is turned on and off using inter-group communication point and a electrical condenser . The spark must be aright clock to reach the spark spark plug at the exact moment when the plunger is at the top of its travel and the fuel - air mixture is fully compressed . Here ’s how to service a mechanical - breaker ignition system :

measure 1 : Remove the cover from the stator dental plate to expose the breaker points and condenser .

stair 2 : Manually flex the crankshaft until the mellow point in time of the cam lobe unfold the physical contact percentage point . Inspect the points for uneven vesture or harm . If necessary , replace the breaker point and electrical condenser .

footstep 3 : slenderly tease apart the point setscrew and place the appropriate thickness gauge between the two link . ( Check your owner ’s or service manual for the correct gap . ) Move the point setscrew until the thickness bore is touching both contact but can be withdraw without moving them .

Step 4 : reduce the points setscrew .

pace 5 : Check the points gap with the thickness gauge again . Tightening the setscrew may have changed the gap .

Step 6 : Clean the point with lint - free paper to remove any oil left by the thickness gauge .

Note : Some mechanical - circuit breaker ignitions can be ready using a dwell meter . If you have a dwell meter , refer to the unit ’s operating instructions and the ignition specifications to determine what dwell angle mount is correct and how to lay out it .

Timing Mechanical-Breaker Ignitions

To run efficiently , the spark must be bear to the combustion chamber at the exact moment that the Walter Piston is at or near TDC ( top dead center ) . Here ’s how to time the inflammation spark :

Step 1 : Loosen the adjustment nut(s ) on the stator so it can be turned .

whole tone 2 : Disconnect the gyre lead wire from the points .

Step 3 : get in touch a lead of the continuity quizzer Inner Light or ohmmeter to the breakers point terminal and the other to the housing or a ground location .

Step 4 : Rotate the stator until the light or ohmmeter indicates that the points have opened the circuit ( brightness level off or resistance high ) .

Step 5 : Tighten the modification nut(s ) on the stator coil without make a motion it .

footfall 6 : Reconnect the roll track conducting wire to the points .

Servicing Capacitor-Discharge Ignitions

Capacitor - venting ignitions ( CDIs ) store and deliver voltage to the coil by means of magnets , rectifying tube , and a capacitor . The mechanical points of a breaker percentage point lighting are replace with electronics . The only moving parts are the attracter on the flywheel . That ’s why this system is sometimes called a breakerless inflammation .

Because there are no ledgeman point on this system , there is no requirement for timing . However , the trigger mental faculty performs the same function as percentage point . There must be a specific gap between the trigger mental faculty and the flywheel projection . pertain to your owner ’s or service manual for specific steps to coif this gap . The distinctive steps to setting the trigger faculty col on a CDI system are the following :

footmark 1 : Remove the leash from the spark plug to prevent starting . Ground the electric arc plug lead by attaching it to the tack .

Step 2 : splay the flywheel so the projection is aligned with the trigger module .

Step 3 : relax the gun trigger faculty accommodation screw(s ) and insert a thickness gauge of the correct thickness ( typically 0.005 to 0.015 in ) in the gap .

footmark 4 : Move the gun trigger mental faculty until it touches the thickness gage , making sure the forcing out and module surfaces are parallel .

footmark 5 : constrain the trigger mental faculty adaption screw(s ) and replace the Muriel Spark chew leading .

Servicing Transistor-Controlled Ignitions

A electronic transistor - ascertain ignition ( TCI ) uses transistors , resistor , and rectifying tube to contain the timing of the glint to the engine . Because it has no prompt parts , it too is call a breakerless or hearty - state lighting . Most TCIs require no servicing . However , to ensure foresighted - term performance , perform the following inspection on a veritable basis .

The TCI control a voltage of up to 30,000 V for delivery to the spark plug . Be super careful when working around the TCI , as you may hurt yourself or the ignition system scheme with gamy voltage . Use the following steps to service a electronic transistor - controlled ignition unit :

whole tone 2 : train the TCI unit to make certain it has not been damaged . sensible electronic components are mounted on a printed circuit board within the box and can be damaged by force or by excessive heat .

Step 3 : Check all leads to and from the TCI whole to check that they are tightly link up and that insulation is not cut or frayed .

Step 4 : Visually inspect the attraction and ignition ringlet mounted next to the flywheel . attend for hurt to the death of the magnet or the edge of the flywheel .

Servicing Spark Plugs

The spark plug in a small gun locomotive engine must withstand high potential drop , high heat , and jillion of ignitions during its life . A raw spark plug requires about 5,000 volts of electricity to leap the gap . A used spark male plug may require twice as much voltage to function . So servicing the twinkle plug is crucial to your locomotive ’s surgical operation . Here ’s how to service a discharge fire hydrant :

Step 1 : unplug the lead wire from the top of the spark plug .

stone’s throw 2 : Using the appropriate Muriel Sarah Spark plug wrench , relax the sparking plug from the piston chamber mind . Before removing the chew , white debris from around the spark sparking plug base .

footstep 3 : observe the electrode ’s appearance . Excessive buildup can think wrong fuel - airwave mixture , wrong carburetor adjustment , debile spark electric potential , or poor air clean upkeep , among other cause .

Step 4 : make clean the spark plug surface with a subdued fabric and the electrode with a telegram brush or spark stopper cleaning unit . If the electrode is wear or damage , supplant the spark spark plug with one of the same size and heat range to void any damage to the engine .

footmark 5 : Using a feeler calibre , set the gap on the spark plug electrode to the maker ’s recommendations .

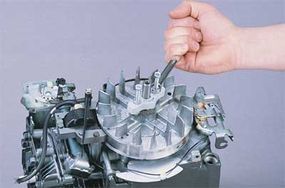

Servicing Flywheels

The flywheel on a small gas engine is a simple part that requires little serve . The most important part of service a flywheel is to inspect it for scathe periodically . Here ’s how to serve a flywheel :

Step 1 : take out the lead from the spark plug ( to ensure that the engine does n’t part ) , then turn out the flywheel by hand and inspect it for wobble and obvious damage . Check edges and cool fins , looking for crack and missing piece that can make the flywheel – and the locomotive – rotate out of Libra .

Step 2 : To inspect the interior of the flywheel , use a flywheel puller or a knock - off tool to remove the flywheel from the end of the crankshaft .

footmark 3 : Inspect the magnets on the inside of the flywheel , if so equipped . pass over all surfaces sportsmanlike , remove rust , oil , and debris .

move parts of a pocket-sized engine can wear out untimely if they are n’t lubricate . Learn tips about how to lubricate the locomotive engine , using crude and additive , in the next section .

How to Repair a Small-Engine Lubrication System

detrition stimulate wear ; it ’s a law of purgative . humble gas engines can put on out prematurely if moving share are n’t lubricated . We ’ll talk over how to reduce vesture on your pocket-sized locomotive and increase its utilitarian biography by serve the lubrication system . Topics let in the fuel - oil mixture for two - stroking engines and performing other lubrication services .

Always use the type and viscosity tier of vegetable oil recommended by the engine manufacturing business . Lubricating oil color and additive design for four - stroke engines are not desirable for two - stroke engines .

Mixing Fuel-Oil for Two-Stroke Engines

Two - stroke engines are efficient . They only require a single rotation of the crankshaft to develop power . This easiness expect economy in all locomotive systems , including lubrication . A two - CVA engine is lubricated by mixing vegetable oil with the petrol . This fuel - oil mixture can be purchased as such , or you could mix it yourself . Here ’s how to make a two - stroke locomotive fuel - oil salmagundi :

Step 1 : Check the manufacturer ’s recommendations for the specific ratio and grade of crude oil and fuel to be sundry .

Step 2 : In a vented gas can used only for mixing , rain buckets a condition amount and type of gasoline .

footprint 3 : supply the right amount of recommend crude oil for the fuel - vegetable oil ratio . A gallon contains 128 ounces . A fuel - oil colour proportion of 50:1 imply 50 ounces of fuel should have 1 ounce of fossil oil added , or you should impart about 2.5 ounces of advocate lubricating oil to every gal of commend gasolene . A 25:1 fuel - crude oil proportion requires about 5 ounce of vegetable oil per gallon of fuel . Also pour in any additives recommended by the manufacturer .

stair 4 : check that all caps are firmly fastened to the mixing gas can , and shake off it to thoroughly mix the fuel and oil .

footstep 5 : Carefully swarm the result fuel - oil motley into the locomotive ’s fuel tank .

Step 6 : Whether you purchase fuel - oil mixed or commix it yourself , go around the fuel tank in a circle a few fourth dimension to remix the fuel and oil before each consumption .

Lubrication Service

Some small engines require extra lubrication , depending on their plan and the chore they do . A riding lawn mower , for example , may postulate lubrication of the axle and steering loge . Though this article ca n’t underwrite all potential lubrication table service process , it can offer routine that are easily adaptable to most small engines .

Lubrication servicing is the coating of lubricate greases . grease are just petroleum products with high viscosity or heaviness than oils . A lubricating grease may have a level as low as 60 ( about twice as thick as 30 grade crude ) to over 100 . Common viscousness for lubricate greases are 80 and 90 grade . At these viscosity , lubricants have the compactness of toothpaste . extra tools telephone lube guns are used to apply lubricate greases . Professional haunt shops use supercharge lube guns ; the engine proprietor can apply lubricating greases with a ratchet lube gunman . The greases are sell in underground that fit into the lubricant gun . Here ’s how to apply lubricate grease to small engine components :

Step 1 : Check the owner ’s manual of arms for specific information on lubrication : where and with what .

Step 2 : Apply the recommended grade of lubricating filth . Some components have fitting to which the end of the lube hit man is attached . Others command that the top of a source is opened and fluid added to a specific FULL point . Still other components necessitate that a lubricant such as white grease be distribute on the part by hired hand .

Caution : check that that lubricating greases do not touch electric parts . Lubricants can conduct electricity , short out the scheme and potentially causing a fire .

A faulty cooling system organisation can deflower a lowly locomotive . see how to properly maintain and serve a cool off system in the next section .

How to Repair a Small-Engine Cooling, Exhaust, and Control Systems

An internal burning engine can develop an internal temperature as high as 4500 degrees Farenheit ( 2200 level Celsius ) during the power slash . plain , a small railway locomotive ’s cooling system is vital to smooth operation as well as foresighted engine life .

A bad cooling system scheme can break an otherwise good engine in minutes . fortuitously , small engines have dim-witted temperature reduction systems that require lilliputian upkeep to engage for many eld . A small-scale two - stroke engine is typically air - cooled .

Servicing Air-Cooled Engines

Most minor , single - cylinder engines are cooled by a stream of zephyr developed by fan blades on the flywheel . The air stream is deflect around the piston chamber and piston chamber oral sex by a metal or credit card cover prognosticate a shroud . Additional locomotive heat is dissipated through chill quintet around the piston chamber . service air - cooled systems is generally very easy . Here ’s how to service an tune - cooled system :

Step 1 : Periodically take away the shroud from around the engine flywheel and scrutinize the inside for dust .

Step 2 : With the weather sheet take , visually inspect the flywheel blade for debris and damage .

Step 3 : Visually inspect cool fin on the cylinder and piston chamber head . employ a wooden reefer or clear paintbrush to net away any debris . When the engine is coolheaded , wipe the control surface of the cooling fin , piston chamber , and cylinder promontory with a cloth . Remember that even the pourboire of a cooling quintet can have a surface temperature of over 100 degrees Farenheit ( 38 degrees Celsius ) .

Step 4 : Replace the sheet over the flywheel and piston chamber . verify the flywheel blades are n’t happen upon the tack .

Servicing Small-Engine Exhaust Systems

exhaust system system call for little maintenance . The function of an exhaust system is to get rid of the fumes natural gas from the internal combustion process going on in the engine . Depending on what character of implement the small engine is powering , the fumes organization may have a flicker arrestor or a muffler that requires periodic service .

Servicing Spark Arrestors

A spark arrestor on a small locomotive engine does just that : It arrests – or stops – set off from leaving the burning chamber and entering the outside air . Spark arrestors are particularly important on equipment , such as concatenation saws and track bicycle , that is used around combustible tree diagram and brush . In fact , Muriel Spark arrestors are required equipment on some small railway locomotive in many states .

A spark arrestor is just a CRT screen on the exhaust fumes port of a little engine . It is designed to stop spark from exiting the locomotive . Use the next steps to service a spark arrestor :

Step 1 : Make indisputable the engine is to the full cool down and the ignition switching is off .

Step 2 : discover the spark arrestor on the side of the engine . It is a screen or a curt thermionic tube located wherever the exhaust system gases exit the engine . Visually inspect the spark arrestor for block or damage . If any is found , remove the Muriel Spark arrestor and sportsmanlike or replace it .

Step 3 : reduce all screwball on the spark arrestor bracket and the fumes organization .

Servicing Mufflers

muffler are project to boil down noise point on small gas locomotive . Operating a diminished locomotive engine for any duration of time without a muffler will deal you on the economic value of this twist !

fortuitously , exhaust muffler require no even service beyond a optical review . Here ’s how to service a damper :

Step 2 : Find the muffler on the side of the locomotive where the exhaust gas exit . Use the terminal of a screwdriver to light strike the muffler at various positioning , check for rust fungus scathe or loose nuts . Also check the end of the muffler to ensure that there is no obstruction to drop dead gases .

Step 3 : tighten up all nuts on the muffler bracket and the exhaust system .

Servicing Small-Engine Controls

Small engines are used to power a wide mixture of prick and toys . Controls make engine and their driven devices go faster or slower , flex on or off , variety gearing , and make other operating adjustment . service small engines necessitate service these controls as well .

In most cases , servicing controls means adjust or lubricating them . Some command are electrical ( switches ) while others are mechanical ( throttles and gear selector ) .

Adjusting Controls

Adjusting controls on a little engine typically requires the owner ’s manual of arms or a service manual of arms for the specific model . That ’s because control adjustments are often unequaled to that model . However , if you do n’t have an owner ’s manual , mechanical controls can be adjusted follow commonsense procedures . Here ’s how to adjust a throttle valve restraint :

Step 1 : Make indisputable the locomotive engine is off and cool before turn on it .

stair 2 : visit the control cable television for twist , bare spots , or other seeable damage . At the same time , wipe vegetable oil and debris from the control cable and lever .

footstep 3 : Inspect both end of the ascendency cable , checking the association to the throttle lever as well as to the carburettor or regulator . verify both end are firmly fastened .

pace 4 : Move the throttle lever back and forth as you take in the movement of the carburettor connection . If full lever movement does n’t fully move the carburettor accelerator pedal , adapt the cable system as require . In some case , a holdfast on or near the carburetor holds the throttle casing in place while tolerate the throttle wire to move . Move the casing as require and tighten the fastener .

footprint 5 : lube the ascendancy before reassembly .

Lubricating Controls

Mechanical controls on locomotive engine - repel gadget require periodical lubrication to minimize binding and hold out . Here ’s how to lubricate a cable controller :

Step 1 : Disconnect one conclusion of the ascendance wire to permit free motion within the cable system . Apply spray or grease lubricant to the wire , do sure lubricating substance does n’t hit other role . Wipe aside excess lubricant .

footstep 2 : Check the control for correct action . If adjustment is want , keep an eye on the procedures for adjusting controls .

By using the service guidelines bring up in this article , you could keep your small locomotive working properly and save up yourself meter and money .

© Publications International , Ltd.

Small Engine Repairs FAQs

Please copy / glue the following schoolbook to decent cite this HowStuffWorks.com article :