morphological job in wooden article of furniture can be defined in terms of three things : the cloth itself , the fashion it ’s put together , and the mode it function .

The textile itself is the problem when a part is demote , warped , or missing . The way it ’s put together is involved when spliff fail or parts are n’t jibe in good order . The way a piece of piece of furniture function count on both material and construction , and functional job can always be traced to one or both of these seed . Nothing can turn an all - around failure into a lineament piece of article of furniture , but with a few canonical repair techniques you’re able to handle most structural piece of furniture problems . In this clause , we ’ll discuss some of those techniques that can help you keep your wooden piece of furniture in estimable , usable condition .

Rebuilding Loose Joints

When a joint fail , you have two problem to deal with : the straightaway functional problem and the farsighted - condition effect of the failure on the rest of the frame . A loose joint that ’s not repaired today may not kick downstairs tomorrow , but it will put stress on other roast . In a week ’s time , one wobbly peg may become two . To prevent simple morphologic problems from turn into more serious ones , loose or separated juncture should be recreate immediately .

Gluing

The mere root is unremarkably the good one , in repairs as well as in refinishing . When you get wind a loose joint , first check that the nooky ( if any ) are tight ; then attempt to repair it with an adhesive agent : plastic resin , epoxy glue , or resorcinol . Force the adhesive agent into the loose marijuana cigarette with a glue injector . If you’re able to , wiggle the joint to distribute the adhesive agent . Clamp the joint for about two days , until the adhesive material is all cured . If possible , strengthen the paste joint with a glue block , as detailed below .

After gluing the liberal joint , put the piece of piece of furniture back into service . match the articulation again in a few weeks . If it has worked promiscuous again , it ca n’t be permanently restore by regluing ; you ’ll have to reward it , resecure it , or rebuild it completely .

Reinforcing: Glue Blocks and Steel Braces

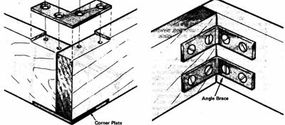

Glue cube , the original furniture twosome , are strong small-arm of Grant Wood used to reinforce corner articulation and provide additional support . sword corner shell and slant dyad perform the same function , but they can detract from the appearance of the man of piece of furniture , and they can also lower its value . For this cause , glue block are still an important part of furniture repairs . Valuable pieces of article of furniture , antiques , and good reproductions should always be repaired with mucilage mental block or else of steel brace when potential .

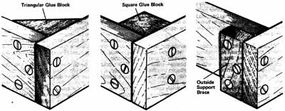

Glue cube for street corner braces can be either hearty or triangular . Square stoppage are used in the main as outside support brace or on long joint , such as the inner corners of draftsman , where cutting a trigon would be impractical . In most cases , triangular gum city block are preferred .

Glue block can be bring down from any square stock , but hardwood is prefer . To make a glue block , cut a square man of wood in half diagonally . The large the opus of wood , the great the gluing surface of the block . The duration of the blocks will depend on the project ; on average , 2 inch is tolerable . To strengthen chair and mesa leg , trim triangular orthodontic braces that are as turgid as necessary from 1 - column inch nominal boards . At the right - angle corner of the block , cut off a diagonal or make a notch to fit around the leg . For brace , 1 x 2 lumber work well .

To install a triangular glue block , fan out adhesive on the two right - angle side or boundary . Set the stop into the corner and twist it somewhat to diffuse the adhesive on the bonding surfaces . Small glue blocks can be strengthened by nail driven through the block into the furniture frame ; drill pilot holes for the nails to make certain you do n’t cleave the wood . To tone up chair and tabular array braces , drive three screws through the occlusion and into the frame , one jailer directly into the corner and one flat into each side , at an angle to the inside pulley block edge . Predrill the nookie holes for the block in both the cube and the figure .

Sometimes a box spliff is hold by a brand bracket instead of a glue block . If the leg wobble , first make certain the crank that holds the bracket is securely tightened . If this does n’t solve the problem and the bracket is go down into notch in the framing , it may not be seated properly . hit the ball and reseat the bracket ; then replace the freak securely .

Gluing and bracing may not be sufficient to prop up up a loose joint , so you need to have intercourse other ways to manage more complicated problems . Learn some advanced fixing techniques in the next section .

Resecuring and Rebuilding Loose Joints

Some loose piece of furniture joints are going to require a little more attending to make them structurally fathom . Although resecuring or even rebuilding a juncture may take extra time , you could achieve either one with some advanced repair techniques .

Resecuring: Screws and Glue

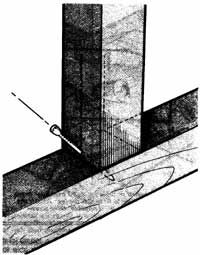

If a slack joint would be difficult to take apart , you may be capable to puzzle out the trouble with a foresightful screw . First align the joint and drill a cowcatcher maw for the screw . Then expatiate the top of the archetype fix so that a small composition of dowel pin can be installed over the nookie head . cake the screw with mucilage , and drive it into the spliff so that it draw out the joint tightly together . Before you reduce the screw , seek to force adhesive into the loose marijuana cigarette ; this will aid strengthen the reefer . Then tighten the screw firmly .

To cover the screw head , veer a piece of dowel ( wooden pin ) to fit the enlarged hole . It should be slightly long than the porta , so that the end of the dowel will protrude slightly above the surface of the frame . Insert the dowel plug with glue , make certain the conclusion of the joggle is flush with the head of the screw , and rent the glue dry out completely ; then carefully cut the end of the dowel flush with the surface , and sand it smooth . You ’ll plausibly have to refinish the frame so the dowel match , and you may want to instal sour dowel fireplug at the other joints in the frame so that they match . The dowel will give the material body a handmade pinned or peg look .

The screw propeller / plug trick can also be used to repair slack round and back , but the pieces involve must be with child enough to take on the screw and dowel . small-scale parts such as turnings and slats may break open when a screw is repel into them .

For the strong screw - reward joint , the screw should be drive into a part of dowel instead of the physique itself . This is n’t always possible . If you could , dismantle the stick , drill a hole at the nooky point , and plug away the fix with a dowel pin , gluing the dowel into place . Then reassemble the joint with a piece of tail and glue , as above . If you want to hide the brain of the fucking , enlarge the golf hole for a dowel plug or set the jailor slenderly and fill the depression with wood makeweight .

Rebuilding: Disassembly and Doweling

reconstruct a spliff – or a series of joints – is not as tough as it might fathom , although it does require a good hatful of patience . You must work slowly to verify all the component part are in the veracious places and all parts fit tightly . To disassemble the joint , draw out it cautiously apart . If it does n’t come apart easy , use a rubber or wooden mallet to tap the physical body pieces apart , but be careful not to damage the wood .

Do n’t look out on the possibility that the joint was forgather with nails or screws as well as adhesive . In this case , you should get rid of the fasteners before you break the adhesive material . If you ca n’t remove them , break the adhesive bond and pry the articulation apart very carefully . Do n’t force the joint asunder . If the nail or piece of tail are imbed too firmly , you ’ll split up or splinter the wood . If prying would damage the forest , consider saw the marijuana cigarette apart . utilize a metal saw with a thin leaf blade that will go through metal and not leave a wide slice .

After the joint is disassembled , it must be exhaustively make clean . If the old adhesive material is brickle or crumbling , scrape it off with a knife or a minute chisel . If it ’s hard to remove , utilise emery paper , blistering piss , or a hot acetum solution . You must bump off all grime and old adhesive . Whatever method you employ , be very thrifty not to damage the wood or the roast wo n’t fit out together right when you reassemble it .

Structural problems are most common in chairs and tables , and the joints involved are usually mortise - and - tenon ( a prong or tongue of woods assure in a cakehole in the adjoining piece ) . In most cases , the tenon ( prong or tong of wood ) is worn or broken . If the damage is n’t too sorry , you may be able to exhaustively clean house the joint and then reassemble it with epoxy , which is a good joint filler as well as a bonding agent . pass over off any excess epoxy glue after assemble the joint , and clamp the juncture until the epoxy is all ironical .

Keep the patch of piece of furniture out of military service for a week or so to make certain the glue has cure properly . If the tenon is badly damage or if the joint was saw aside , you ’ll have to reconstruct the joint with hardwood dowels in lieu of the tenon – two dowels are adequate for most joints . Use dowel about the same breadth and about twice the length of the damaged tenon . trim off the damage tenon , and take any busted wood from the mortise . punch the mortise whole with a woods plug , glued in and trim flush with the surface . Then use dowel to get in touch the parts again .

To make the maw for the dowels – in the tenon base and in the plugged mortice – apply a doweling gigue , clamped to the sharpness of the wood and adjusted to center the joggle holes . Dowel center points can also be used , but they are n’t as exact as a jig . Drill the holes to a total profoundness of about 1/4 column inch deep than the length of the dowel to permit for glue buildup under the dowels .

Score the position of the dowels with plyers and round the ends somewhat with emery paper or a file . This improves glue distribution and makes insertion well-to-do and more accurate . use glue to the dowel , and insert them into the holes in one side of the joint . Then coat the edge of the Natalie Wood with glue , and err the other joint piece onto the dowels . solicit the joint together with a synthetic rubber or wooden beetle , pass over off any glue that oozes out of the joint , and clamp the joint steadfastly for about two days , until the glue is all arrange .

on the loose joints on wooden piece of furniture can cause long - term impairment to the rest of the chassis by increase stress on other joints . But screw how to repair or interchange any joint trouble can help you keep all of your furniture from being thrown away too soon .

© Publications International , Ltd.