Controls

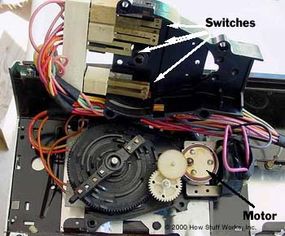

The controls for this machine were designed beforemicrocontrollerswere being used in contrivance . In fact , there is not a single resistor orcapacitorin the whole machine . First , let ’s take a expression at thecycle switch– you ’ll be amazed at what is privileged .

The round electric switch has the job of determining how long the dissimilar parts of the bicycle last .

Inside the switching is a little motor equipped with a very largegear reductionthat make the control dial turn very lento . In the top one-half of the switch , there is a set of sixcontacts . These are motivate by the small pieces of metal in the plastic subdivision on the telephone dial . As the telephone dial spin , bumpson the telephone dial raise and lower the six metal pieces , which closely and launch the contacts in the top one-half of the switch .

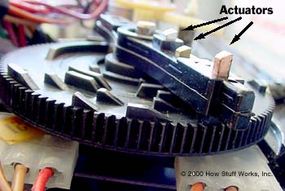

If you reckon at the shape of the bumps , you could see why the dial on the washer spin only one path : The front side of the bumps has a incline that raises up the metallic element pieces step by step ; but the back side does n’t , so if you seek to turn the pommel backward , the metal pieces wedge against the bumps .

This bumpy charge plate disk is really the software program that feed your lavation car . The length of the bumps determines how long each part of the cycle last , and the length of the space between swelling determines how long the machine hesitate before moving on to its next task .

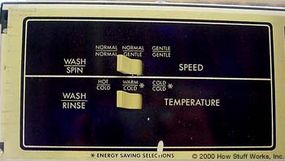

Thespeed and temperature controlswitches are much simple than the rhythm control switch .

These transposition control the speed of the motor and determine which of the red-hot / cold-blooded water supply solenoids will open up during the wash and the rinse rhythm . If raging is selected , only the hot water solenoid valve will spread out when the machine fills ; if ardent is selected , both will open ; and if cold is pick out , only the moth-eaten piddle solenoid valve will open .

The velocity / temperature command is pretty uncomplicated . Eachplastic rockerengagestwo set of touch , either orifice or closing the circuit unite to those contact . For each switch , there is always one closed and one open set of contacts .

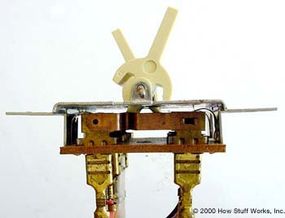

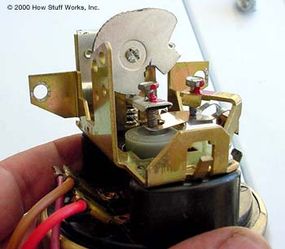

Thelevel sensoruses apressure switchto detect the water level in the tub .

This permutation controls how gamy the tub fills with water .

The big oddment of the hose tie in to the bottom of the bath , while the small ending connects to the electric switch . As the water level in the tub ascent , water rise in the hose also ; but the line in the hose is pin down , so as the body of water rises , the atmosphere is squeeze .

Inside the living accommodations of this transposition is a littlepiston . The pressure in the hose pushes the piston up . When it is raise far enough , it pops up and closes an electrical contact . This fixed full stop , where the contact is lost , is adjustable , and in the motion-picture show you may see thecam mechanismthat is connected to the adjuster thickening on the control venire of the automatic washer . As the Cam River turn over , it press a spring against thecylinder , making it harder for the cylinder to down up . This signify that the water supply floor will have to go up some more before the pressure in the hose will be high enough to spark the switch .

For more information , check out the links below .